Your basket is currently empty!

Month: November 2023

Corrosion resistance

Corrosion resistance in pumping stations

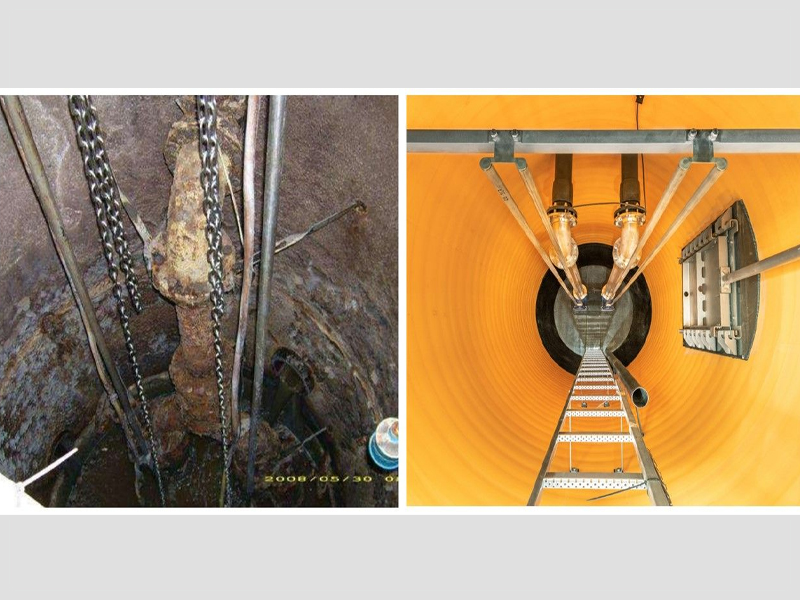

Picture: Above a completely corroded pumping station, below our system with a corrosion-resistant PE-HD shaft and stainless steel fittings.

Why is corrosion resistance in pumping stations so important?

1. durability of the corrosion-resistant PE-HD chamber system and the

Stainless steel fittings.

2. permanent stability of the shaft thanks to corrosion-resistant

Interior made of PE-HD.

3. permanent watertightness of the stainless steel fittings and the

PE-HD manhole.

4. reduced sludge deposits due to the smooth shaft material

made of PE-HD.

5. gate valves and fittings remain in place due to the corrosion-resistant

Stainless steel permanently operable.

6. safe installation and removal of the pumps is not possible due to the

corrosion-resistant pump feet at any time and permanently.

Load Fluctuations

Optimizing small wastewater treatment plants for load fluctuations

Small wastewater treatment plants are often overwhelmed when it comes to load fluctuations, such as those that occur in hotels, restaurants, clubhouses and sports facilities. The solution? The addition of an overload storage tank!

Why is an overload storage system the ideal solution?

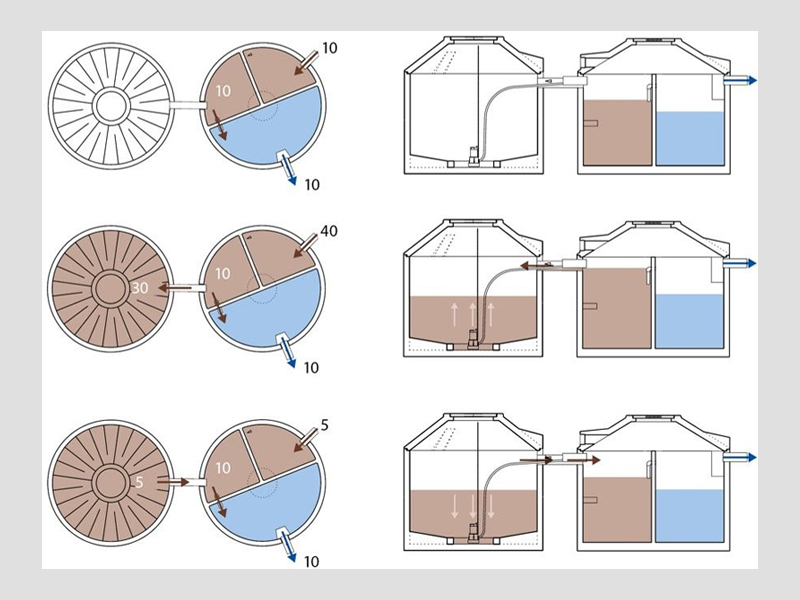

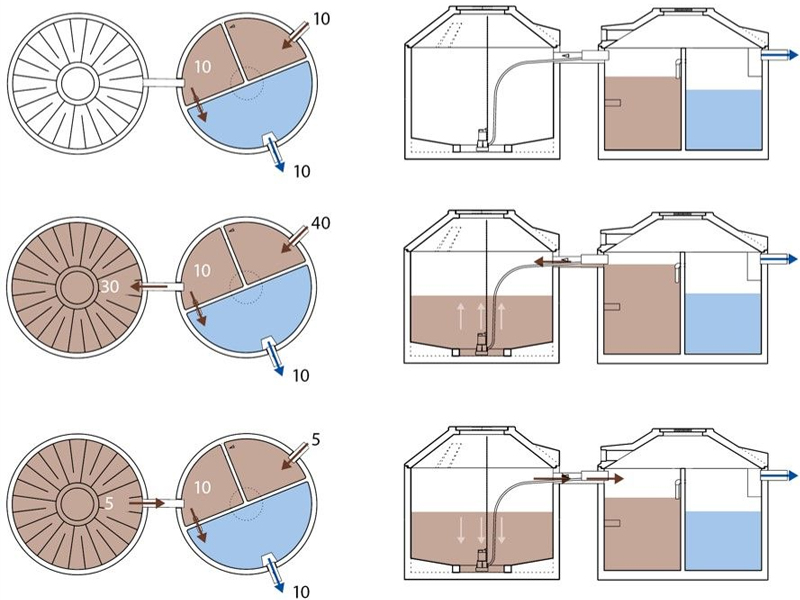

In our example, we show how the overall system deals with short-term peak loads:

- Picture above: The small wastewater treatment plant runs in normal operation with 100% utilisation.

- Centre image: Excess wastewater that exceeds the capacity of the small wastewater treatment plant

is discharged into the overload storage tank.

- Picture below: In times of low load, the energy stored in the overload memory

stored wastewater is returned to the small sewage treatment plant.The advantages at a glance:

- The small wastewater treatment plant remains in normal operation despite peak loads.

- Ideal conditions are created for a stable cleaning performance.

Efficient pressurised drainage

Efficient pressure drainage with cutting wheel pumps

Cutting wheel pumps are the answer to optimized pressure drainage, especially in rural areas. Here, pressure networks score over gravity sewer systems due to their cost-effectiveness with low wastewater volumes and long distances.

Advantages at a glance:

- Cutting unit shreds larger pieces of wastewater, prevents blockages.

- Small cable cross-sections reduce the residence time and minimise

Rotting and odour formation.

- In economical construction, the pressure pipe is installed at a shallow depth.

adapted to the terrain.

Stainless Steel Armatures

Stainless steel armatures in wastewater pumping stations

Why stainless steel? These durable armatures not only offer high corrosion resistance, but are also extremely robust and ensure long-term, reliable performance in pumping stations.

Focus on sustainability: By using stainless steel, we minimize maintenance requirements and significantly extend the service life of the armatures. This not only helps to reduce operating costs, but also contributes to resource efficiency.

Technological excellence: Our stainless steel armatures are unique and have been specially developed for pumping stations to meet the increasing demands for efficiency. We are thus setting another milestone in the development of advanced solutions for wastewater infrastructure.

VARIANT Pumping Station

Pressure drainage with VARIANT Pump Stations

Pressure drainage is an ideal wastewater discharge option for single and multi-family houses in rural areas. Through a VARIANT pump station, all the wastewater is pumped unnoticed along the fastest route to the nearest wastewater treatment plant.

Cutting wheel pumps are the first choice for pumping small amounts of wastewater containing fecal matter. The cutting wheels shred all the larger components of the wastewater during operation, allowing the use of smaller pipe cross-sections. The pipeline network thus remains optimally protected against deposits and blockages.

The wastewater only remains in the closed pipeline network for a short time, so that rotting processes and odor emissions cannot occur. Pressure drainage is ideal, especially for longer distances and difficult topographical conditions. Following the course of the terrain, differences in altitude can be overcome without any problems.

The investment and operating costs of pressure drainage are often significantly more economical compared to gravity sewer systems.

VARIANT pump stations are equipped with the non-return ball valves and reliably protect your property against backwater from the public network.