Your basket is currently empty!

Tag: Nassaufstellung Betonschacht

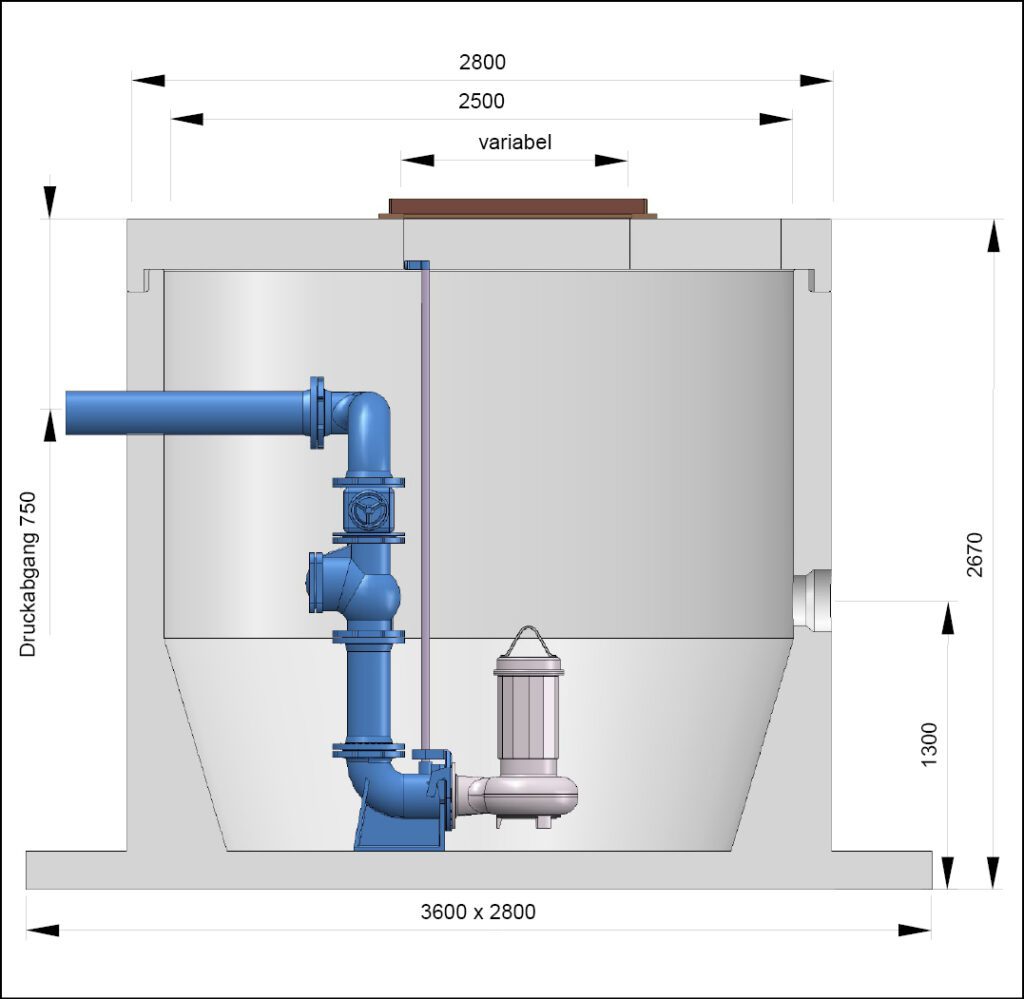

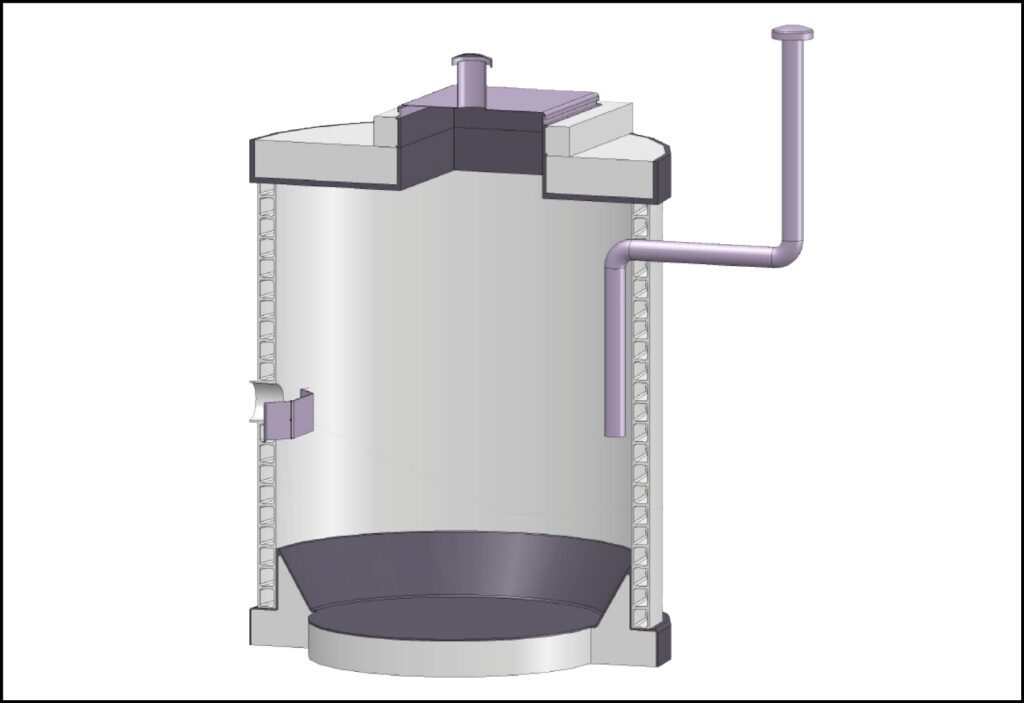

Pumping Station GARANT

Pumping Station GARANT

Features

Robust

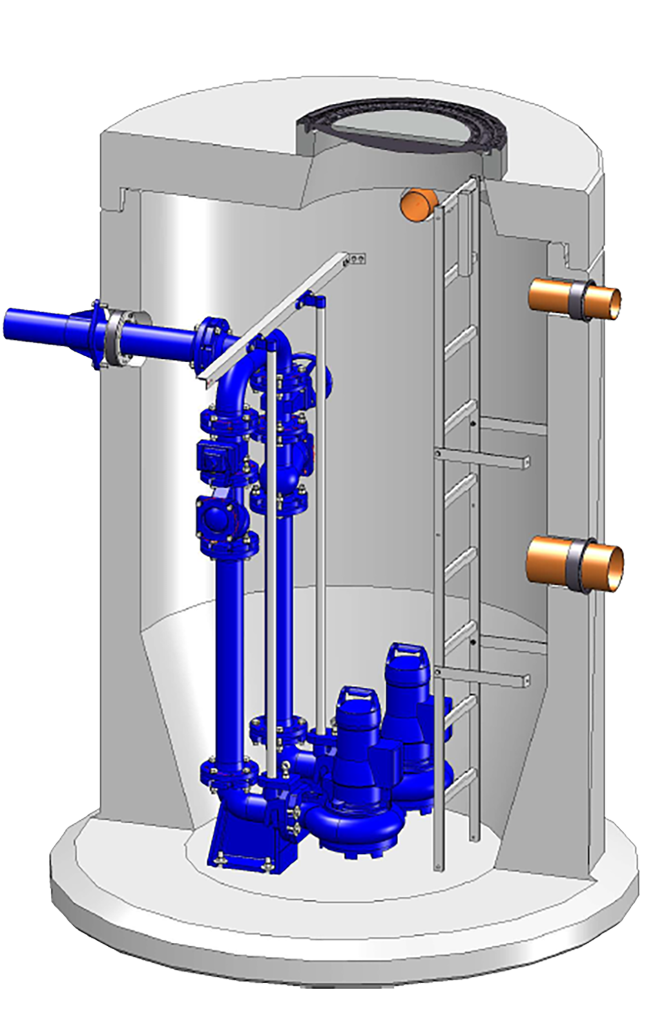

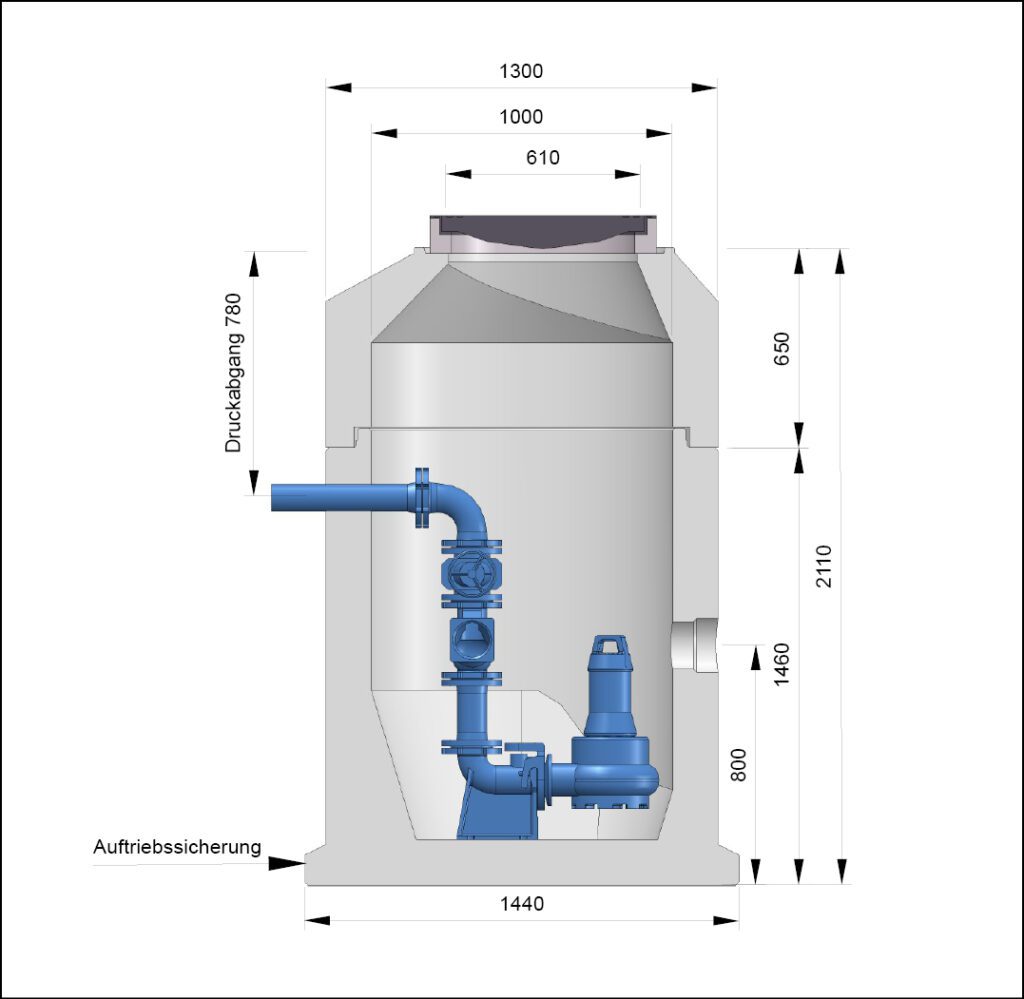

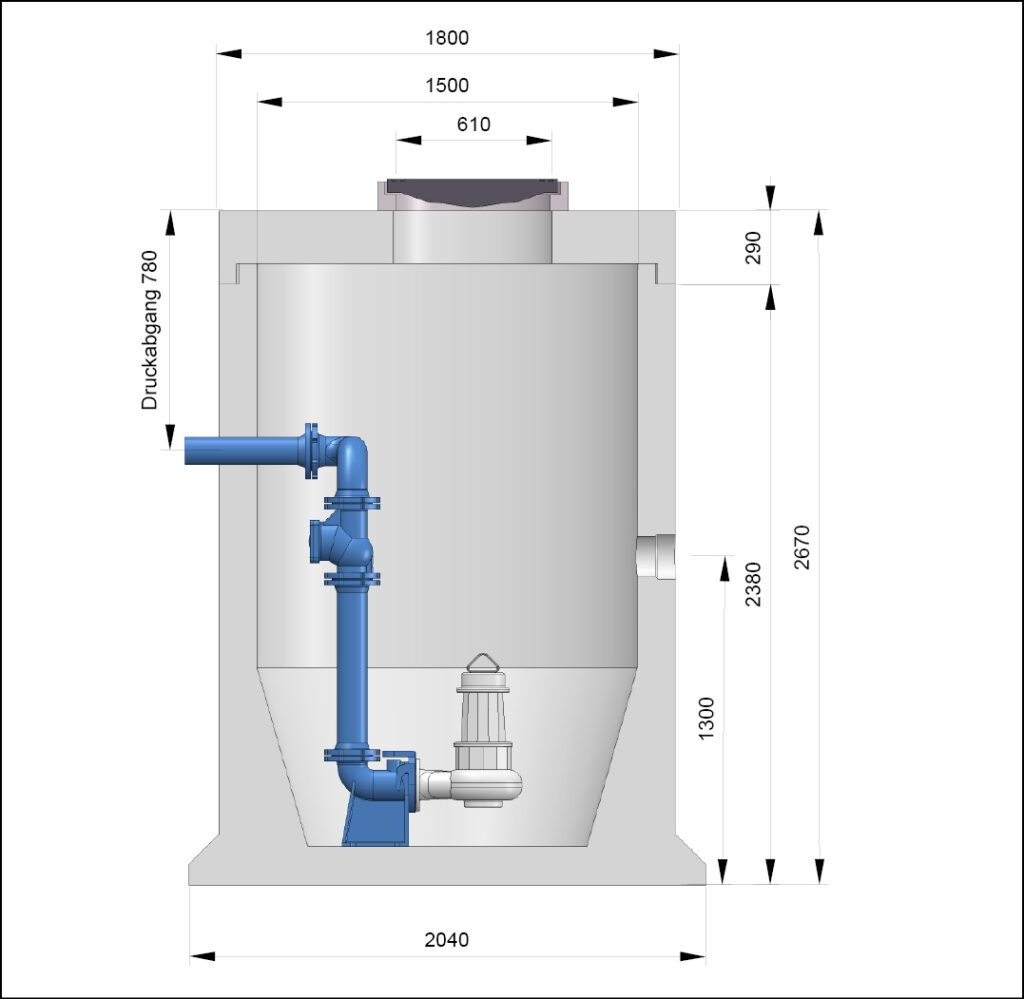

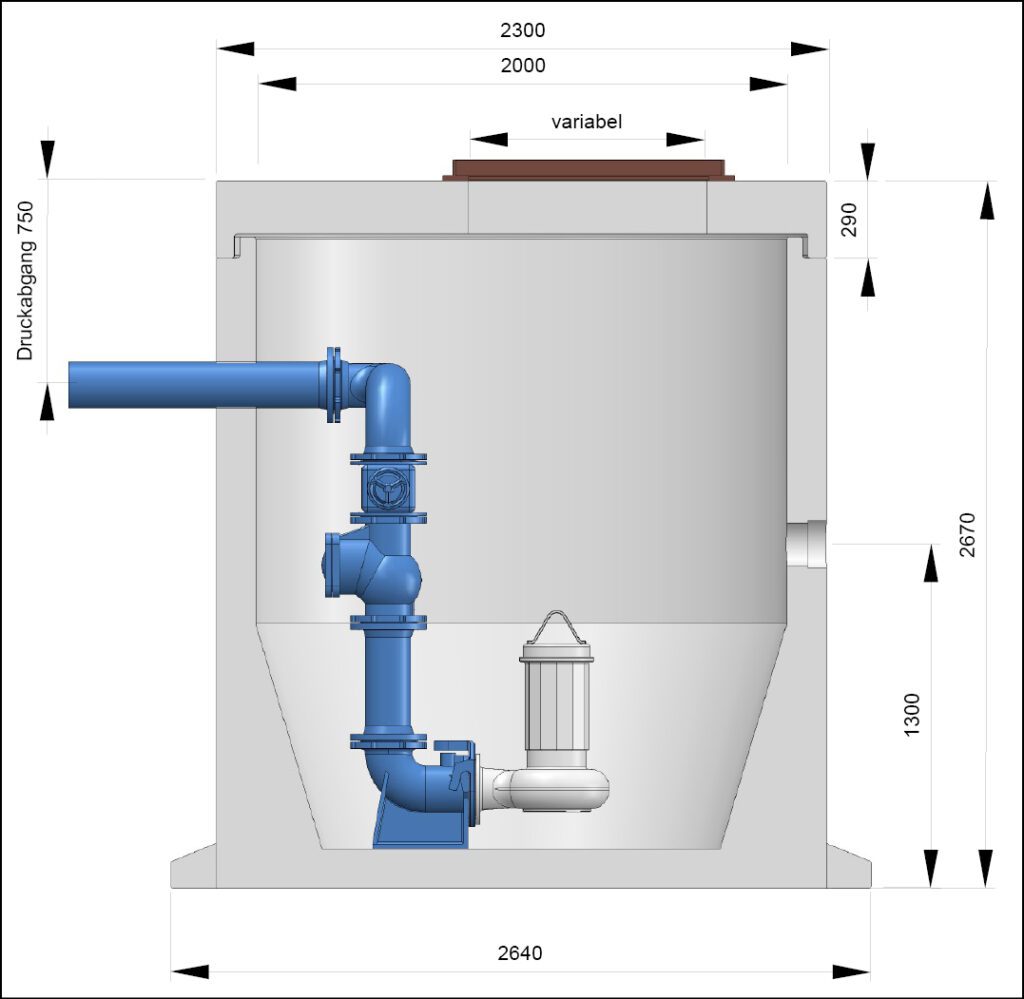

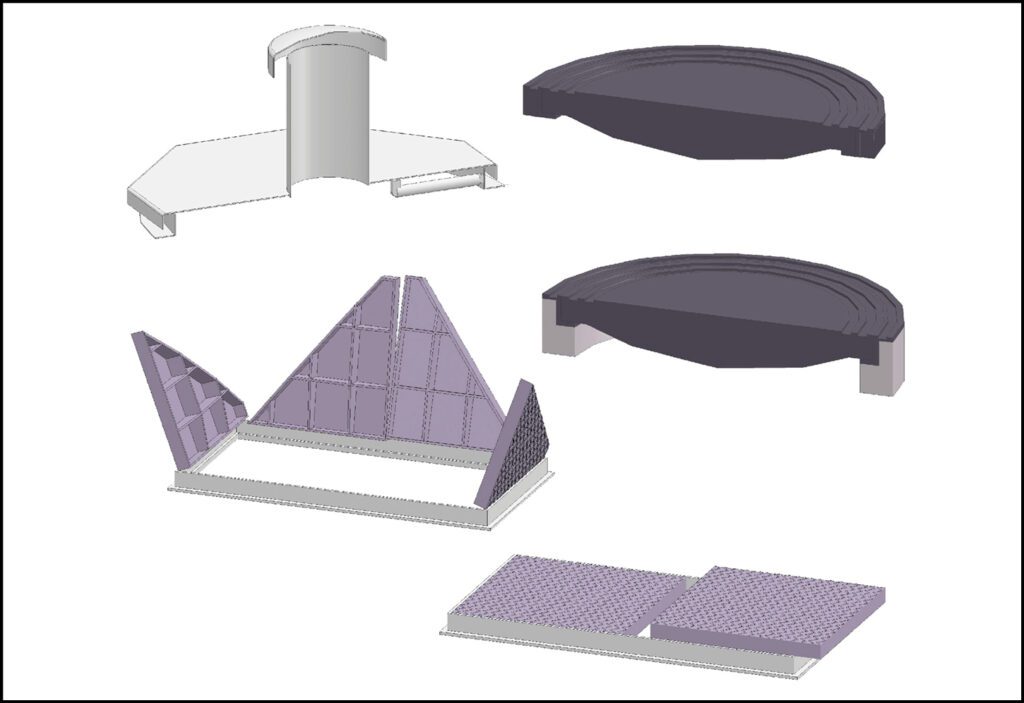

Concrete Shaft Systems have proven themselves over decades for wastewater pumping stations. The precast concrete elements, produced according to DIN 4034 Part 1, are qualitycontrolled and delivered with consistently high standards. Our structures are designed to withstand heavy loads and are perfectly suited for long-term use.

Anti-Buoyancy System

Depending on requirements, an anti-buoyancy system is integrated into the base shaft at the factory as a single cast unit. In addition to the cantilever plate, the high self-weight of the concrete also contributes significantly to reliable buoyancy resistance.

Connections

Pipe connections are factory-made according to the project specifications. We are capable of integrating openings for various conduit systems.

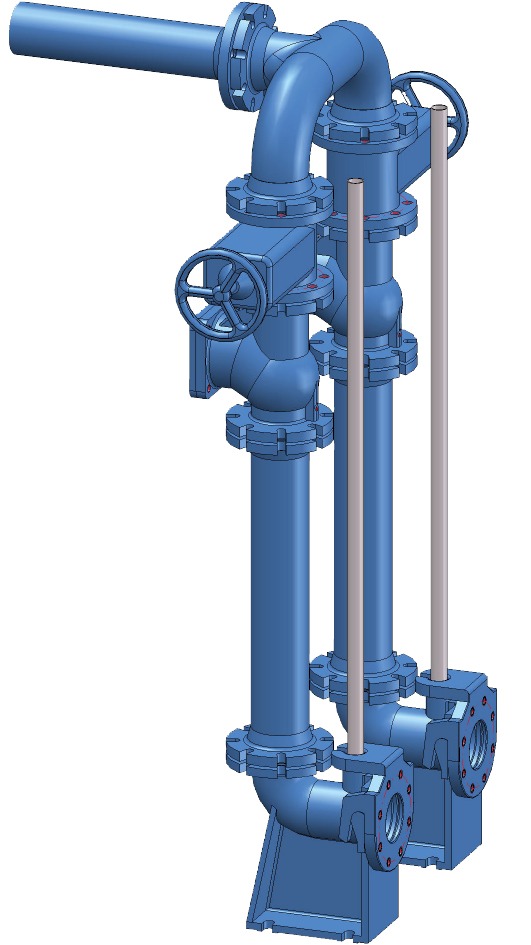

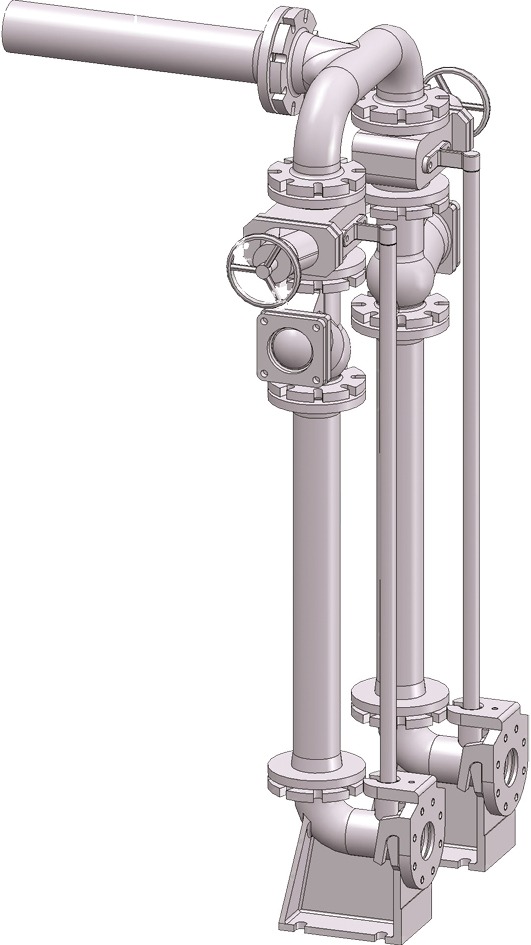

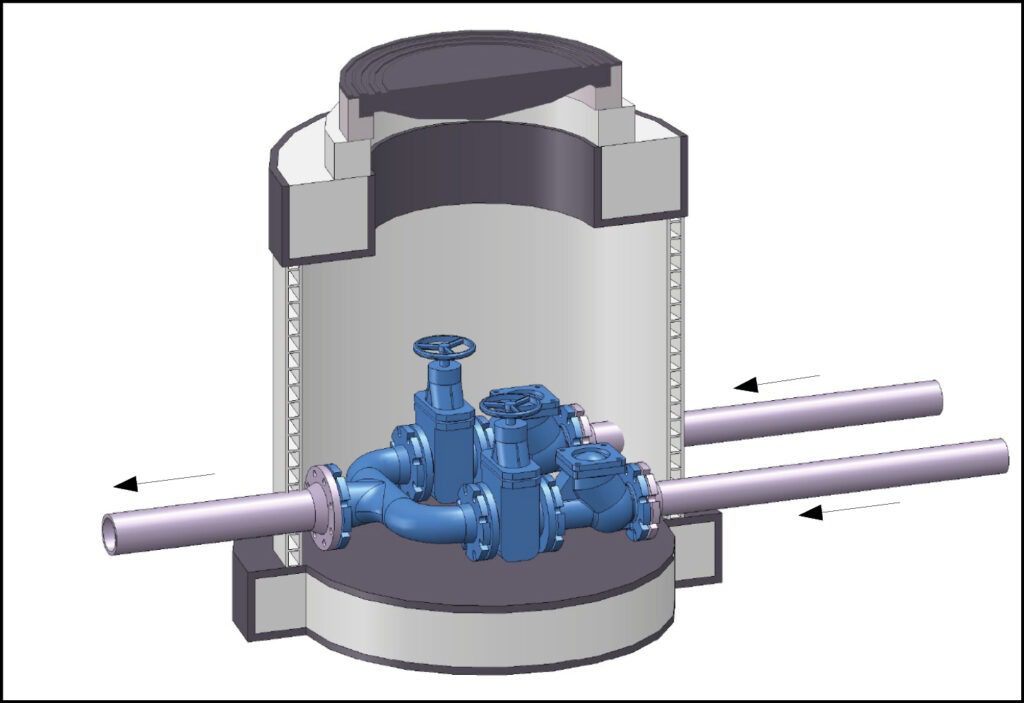

Armatures

Kordes armatures are known for their highly breakresistant materials and low-maintenance design, with few assembly and fastening components. All components are perfectly matched to each other.

Pre-assembled

The armatures are pre-assembled at the factory, allowing for the elimination of complex assembly at the construction site.

Applications

Pumping Stations for Municipal / Industrial Applications

Submersible Wastewater Pumping Stations are ideally suited for municipal and industrial wastewater, as well as surface water.

Special stress factors affecting pumping stations in municipal areas include heavy rainfall, biogas emissions, fats, and fibrous materials. In the case of industrial wastewater, the challenge lies in aggressive chemical loads due to the substances involved. Applications for surface runoff from parking lots and roads not only have to manage heavy rain events but also address the issue of increased salt content.

Each pumping station must be sized and configured to ensure sufficient resistance for long-term use. Depending on the location, structural safety against buoyancy may be necessary, especially in the presence of groundwater. Our ready-to-install pumping stations minimize construction time, significantly reducing costs for groundwater management, wastewater disposal, and traffic disruptions during the construction phase.

Planning

Customized and Individually Designed

A frequently requested service from our company is planning support. The focus here is on the planning of wastewater pump stations, including the calculation of pumps, calculation of pressure pipelines up to the planning of pressure pipe flushing stations. The planning of EMSR and control technology are also among our strengths.

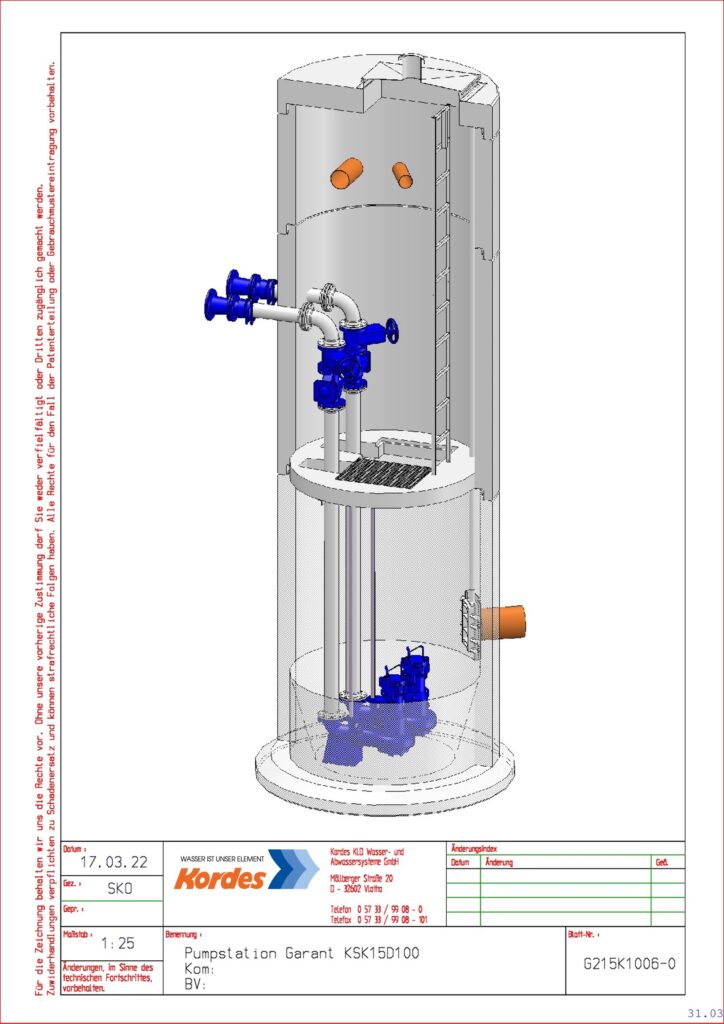

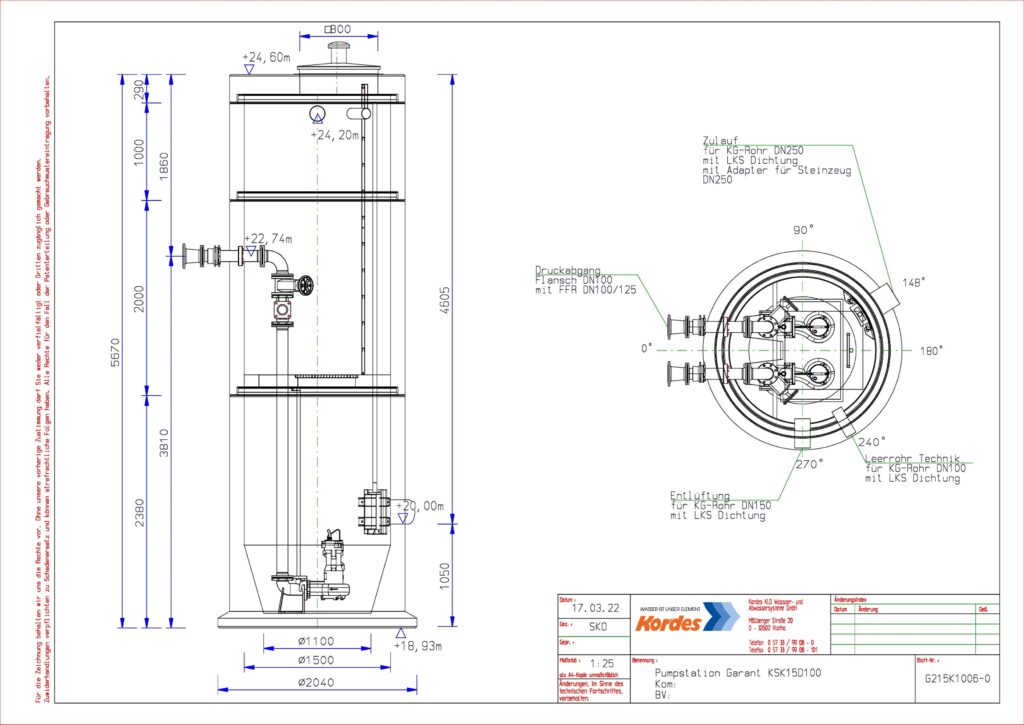

When you place your order, you will receive a detailed 2D and 3D drawing from us for your building project. This serves to visualize your new pumping station and facilitates technical optimization before the start of construction. Only when everything is perfect do we start production.

Shaft Systems

KSK 10

KSK 15

KSK 20

KSK 25

Armatures

100% Ductile Cast Iron,

Powder Coated

DN 80 – 200

Ductile Cast Iron

Powder Coated

and Stainless Steel

DN 80 – 200

100% Stainless Steel

DN 80 – 100- Piping: Stainless Steel, Extendable as Needed Depending on Shaft Depth

- Easy Pump Installation: Pumps Can be Easily Inserted into the Coupling from above without Entering the Shaft

- Pump Removal: Possible at any Time without Shutting off the Gate Valve

- Ball Check Valve: Prevents Backflow into the Pumping Station

- Shut-Off Gate Valve: Allows the Piping to be Closed for Maintenance Purposes

- Optional Features: Flushing Connection, Vacuum Breaker

Armaturen in Edelstahl – Korrosionsbeständig und langlebig

- Simple and Quick Installation with Clamp Flange Connection

- Kordes Pump Base Available with Single or Double Pipe Guide, Compatible with All Pump Manufacturers Featuring a DIN Flange.

- Simple and Quick Installation with Clamp Flange Connection

- Kordes Pump Base Available with Single or Double Pipe Guide, Compatible with All Pump Manufacturers Featuring a DIN Flange.

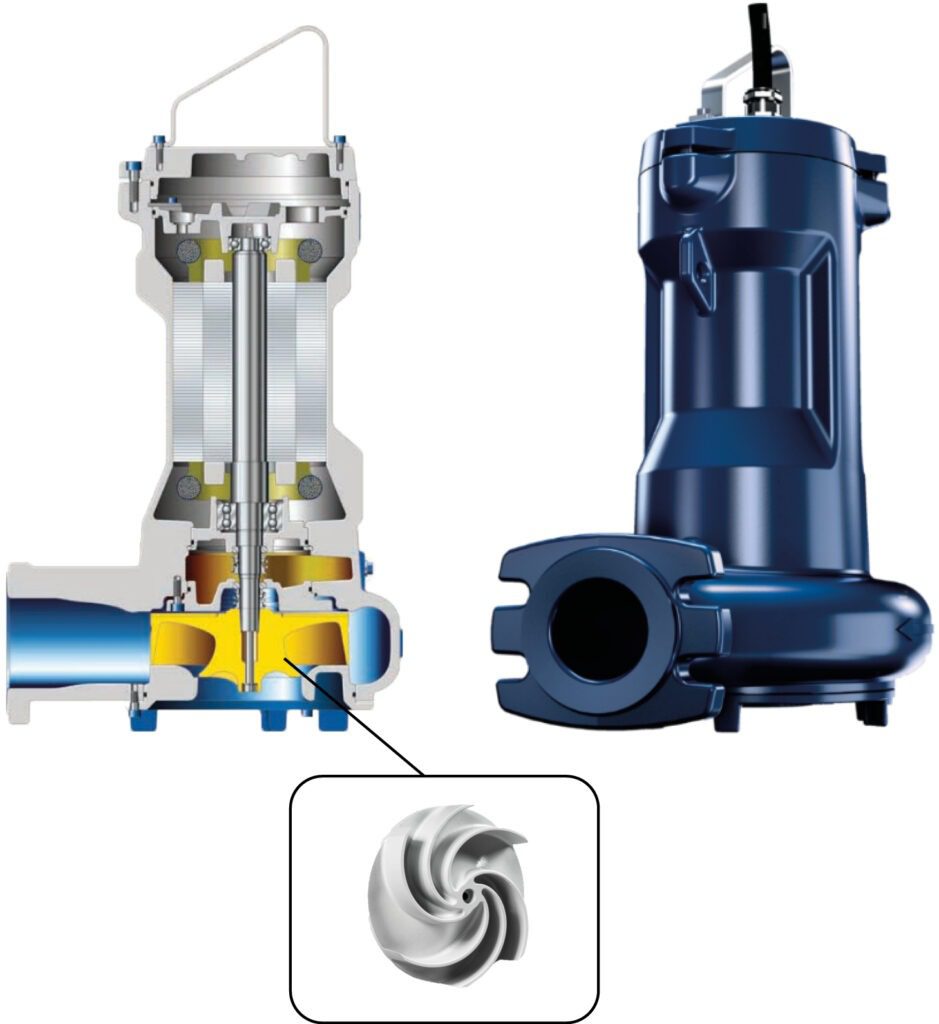

Pumps

For optimal flow performance and velocity, armatures, pressure lines, and pumps must be precisely tailored to the requirements of your construction project. Our range includes pumps with cutting wheel systems for small wastewater volumes with particulates, as well as pumps with free-flow impeller systems. Both types are available with or without explosion protection. For certain wastewater types, pumps with special resistance to aggressive substances are necessary.

Don’t leave the selection of the right pump to chance; let us assist you in making the correct choice. To ensure we offer the pump best suited for your project, we collaborate with leading manufacturers of wastewater pumps. Our armature system is compatible with almost all standard pumps with a DIN flange.

Control Unit

With our Kordes control systems, we can operate single, double, or multiple units. Our controls are used by commercial and municipal facility operators and can be customized with electronic components as needed. For municipal wastewater management, we also provide PLC-controlled systems, complete with process visualization and remote monitoring technology. We are happy to supply a matching control cabinet for your project. At our facility, the control system and desired components are fully assembled and tested in the control cabinet according to your specifications.

WDN Control Unit

- Customizable Control System Design for Municipal Applications

CEN / CDN Control Unit

- Connection: up to 20 kW / 40 A

- Dimensions According to Equipment

- Direct Start, Soft Start, Star-Delta Start

- 3 Potential-Free Contacts with Optional Expansion

- Level Measurement: Differential Pressure, Float Switch, Pressure Sensor

- Touch Color Display: Backlit

- Error Log: Full-text Display

- Manual Operation

- External Lockout of Pumps

- Operating Hours Recording

- Current Measurement

- Thermal Monitoring of the Pumps

- Alerts: Overcurrent, Overheating, High Water, Runtime Monitoring

- Optional Air Injection

- Optional Power Failure Monitoring

- Optional: GSM Modem with Qualified Notifications

Control Unit CEB / CDB

- Connection Capacity: Up to 5,5 kW / 9 A

- B/H/T = 265 x 270 x 145 mm

- Direct Start

- 3 Potential-Free Contacts

- Level Measurement: Differential Pressure, Float Switch, Pressure Sensor

- Touch Color Display: Backlit

- Error Log: Full-text Display

- Manual Operation

- External Lockout of Pumps

- Operating Hours Recording

- Current Measurement

- Thermal Monitoring of the Pumps

- Alerts: Overcurrent, Overheating, High Water Level, Runtime Monitoring

- Optional Air Injection

- Optional Power Failure Monitoring

- Optional: GSM Modem with Qualified Notifications

Accessories

Access Ladder

Pumping stations require a safe entry option. For this purpose, we install stainless steel ladders with safety steps available in widths of 300mm and 400mm. A retractable entry aid provides additional safety when entering. For deeper pumping stations, we offer a climbing protection system or an intermediate platform in accordance with accident prevention regulations (UVV) for fall protection.

Pipe Penetration

For a secure and sealed connection between the shaft and piping, we offer Kordes ConFix sealing insert systems. These systems provide a permanently elastic and tight seal between the pipe and the concrete or PE-HD wall. Pipes made of cast iron, steel, and plastic are gas- and watertight, sealed within core drill holes or protective sleeves. The robust connection is achieved using an NBR rubber ring compressed between two V2A stainless steel flanges.

Plug and Spindle Gate Valves

In the case of pumping stations, it is sometimes desirable to be able to shut off the supply lines for work in the shaft. For this we offer plug-in or spindle gate valves for the appropriate pipe diameter. It is operated mechanically or by an electric drive. The controller can be connected to the BMS.

Shaft Ventilation

For proper shaft ventilation, appropriate stainless steel or PE-HD pipes should be installed within the shaft. To terminate the underground piping, we offer stainless steel ventilation chimneys in DN 100 / DN 150. The stainless steel cover can be optionally equipped with a vent cap.

Covers

We offer shaft covers tailored to your requirements, available in square or round shapes, made from BEGU, cast iron, or stainless steel. The shaft system meets load class SLW 60, allowing cover selection from class A to D.

Armature Shaft

Armatures are typically located within the pumping station, but some operators prefer having them in a separate shaft, which we offer as a prefabricated unit in PE-HD or reinforced concrete. Inductive flow measurement devices or ventilation valves can also be conveniently installed in separate shafts.

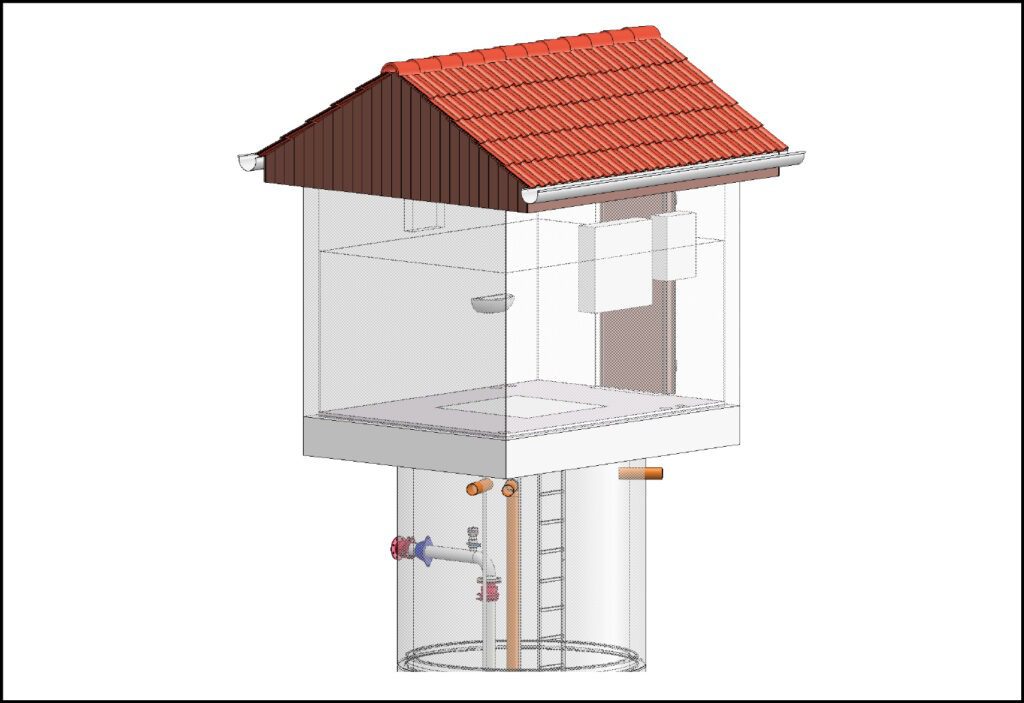

Technical Building

We optionally offer a suitable technical building for your pumping station. We coordinate the equipment with you individually to ensure an optimal solution for future operations.