Your basket is currently empty!

Tag: SBR Kleinkläranlagen AQUA-SIMPLEXair

Kleinkläranlage AQUA-SIMPLEXair

Small wastewater treatment plant AQUA-SIMPLEXair

Features

The purely compressed air driven treatment system

Technology of AQUA-SIMPLEXair

Functions

Treatment in 8-hour cycles, 3 times a day

The cycles in which the individual phases run are 8 hours, so that 3 cycles take place per day.

The excess sludge produced in the SBR reactor is pumped into the pre-sedimentation tank by means of an air lift pump, in regular intervals or as required, and is disposed together with the pre-sedimentation sludge. The SBR reactor is fed and emptied by an air lift pump.

1. filling - Inflow

The wastewater is conveyed from the pre-treatment into the SBR reactor.

2. Aeration

The wastewater is enriched with oxygen from the air by means of a diffuser and circulated. The microorganisms that form as a result, are used to treat the wastewater as activated sludge.

3. Sedimentation

In the sedimentation (settling) phase, the aeration is switched off. The sludge in the plant settles to the bottom. A clear water zone is created in the upper area. This is where the treated wastewater is now located.

4. Clear wastewater discharge - outlet

The treated wastewater is now pumped out of the clear water zone. The new cycle can begin.Treatment performance

The right technology for each application and the right container is important, no matter whether new construction or retrofitting.

The Kordes delivery program offers an extensive product range. All AQUA-SIMPLEX wastewater treatment systems are modularly expandable. This means that the technology can be adapted to the respective conditions at any time.

Minimum requirement with removal of carbon (BOD5, COD).

Here, nitrogen is biologically degraded by nitrification and denitrification.

Advantages

- The small wastewater treatment plant for retrofitting and new construction

- Plug-in compressor with power and compressed air connection

- A compressor brings the necessary oxygen into the SBR reactor

- Including sampling module on the outlet pipe

Mounting system

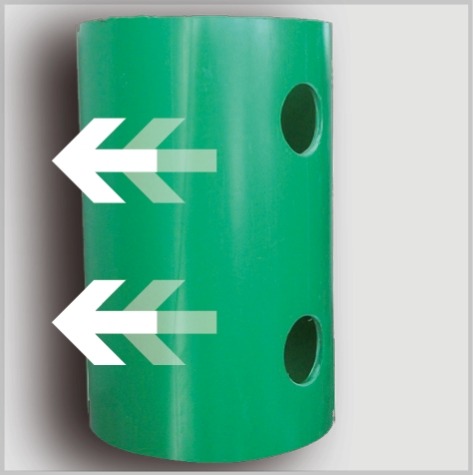

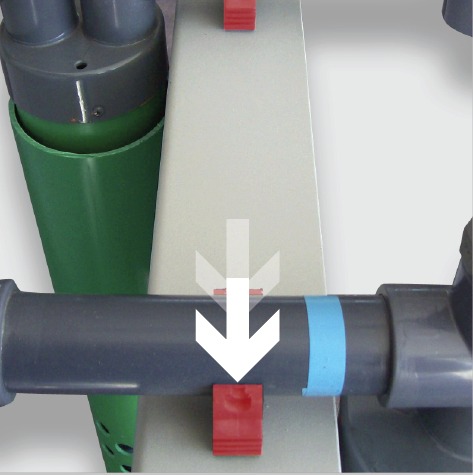

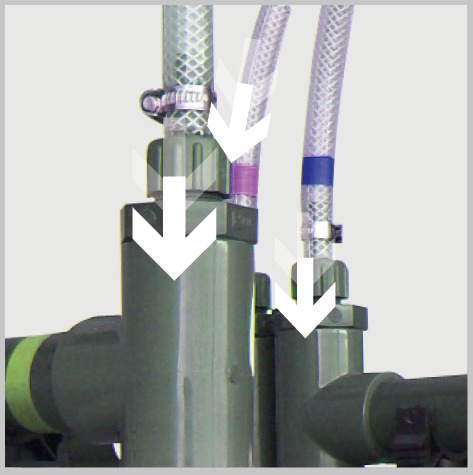

The AQUA-SIMPLEXair quick mounting system

First, the sliding tubes are screwed to the partition wall

Then feed the air lift pump into the sliding tube

Securing is done by a clamp (shown here in red), which is fixed on the partition wall

In the last step, the compressed air hoses are screwed on - done!

Technical details

Control unit + compressor

Display

Level control

SBR technology

Screw tops

Tube pack

Sampling container

Sampler (optional)

The small wastewater treatment plant only with air operation for the single and multi-family house

New system

Supplied in concrete (ring or compact construction) or plastic tank

Retrofit

For the existing tank with a precisely prepared treatment technology

Air technology

The septic tank contains the membrane aerators for the oxygen supply and the air jacks for pumping water. Everything is supplied exclusively with compressed air!

Load fluctuations

With AQUA-SIMPLEXair the daily load fluctuations can be effectively absorbed. A permanent underload is possible to a small extent.

Water level measurement

The water level is measured via dynamic pressure. This regulates the wastewater treatment plant for normal, economy and holiday operation.

Dynamic aeration

The dynamic aeration takes place as required. Here, energy savings of up to 30% can be achieved compared to conventional SBR treatment plants.

Energy demand

Demand for 4 Pe: 264 kWh/year

Demand for 8 Pe: 333 kWh/year

Demand for 12 Pe: 432 kWh/year

Demand for 16 Pe: 476 kWh/yearExpandability of the treatment plant

- Phosphate elimination with P-module

- Carbon dosing with C-module

- Remote data transmission for error messages via SMSCompletely ready to plug in

The control system and the individual units are connected with plugs and screwing locks. This makes it possible to replace spare parts quickly and inexpensively without a service technician.

Long-term observation

The compressor has an operating time of approx. 18,000 hours.

Demand for 4 Pe: 2.714 kWh/year

Demand for 8 Pe: 3.482 kWh/year

Demand for 12 Pe: 3.935 kWh/year

Demand for 16 Pe: 4.355 kWh/yearControl unit

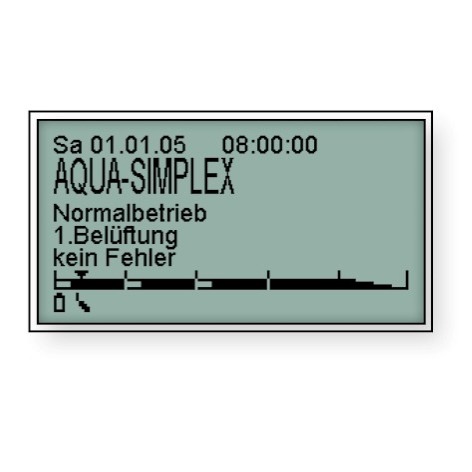

In addition to the process control of the wastewater treatment plant, operating hours and error messages are also stored. All operating data are clearly displayed via the full text display. The plug-in control unit also includes a serial interface (RS232) for PC connection. The standard cable length is 15 m. Optionally 25 m or 35 m.

Maintenance

2 times a year

Model variants

4-16 Pe

Single tank - partition wall suspension

4-16 Pe

Two tanks - partition wall suspension

4-16 Pe

Two-tank chain suspension

20-28 Pe

Two tanks - partition wall suspension

20-28 Pe

Two-tank chain suspension

32-50 Pe

Three tanks partition wall suspension

32-50 Pe

Three tanks chain suspension