Your basket is currently empty!

Tag: Variant

Pressure drainage VARIANT

Pressure Drainage VARIANT

Product selection

Mehr Info’s

Applications

Pressure Drainage VARIANT

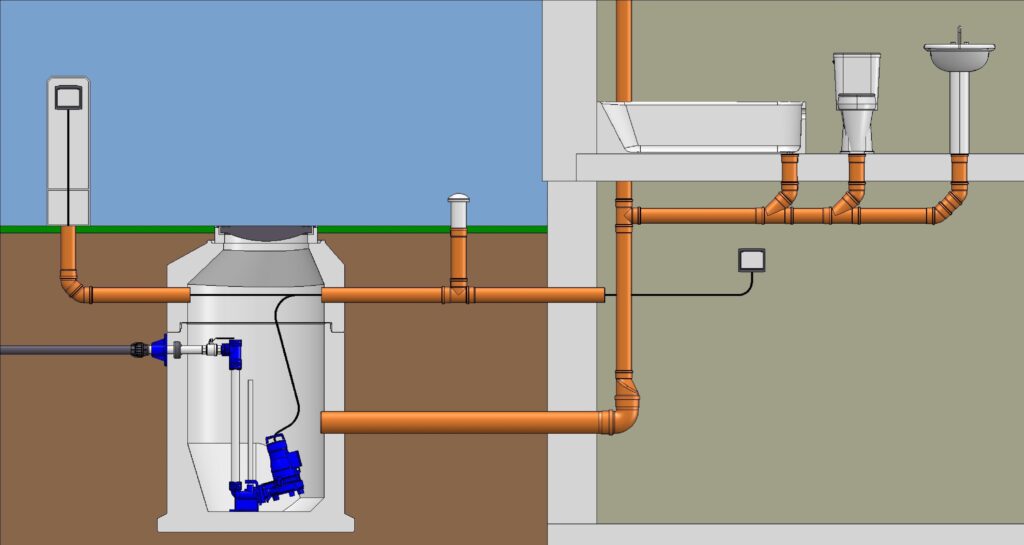

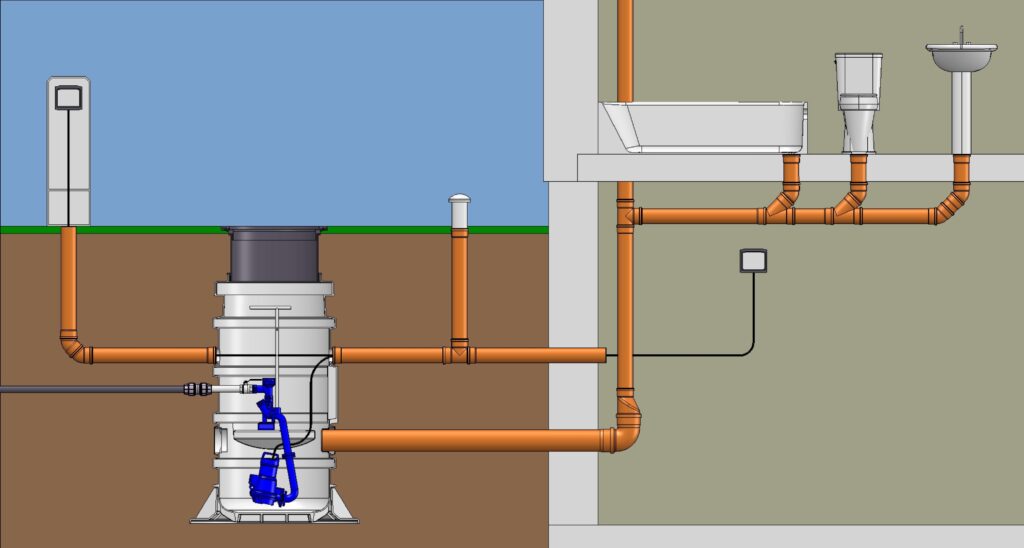

Pressure drainage is an ideal wastewater discharge option for single and multi-family houses in rural areas. Through a VARIANT pump station, all the wastewater is pumped unnoticed along the fastest route to the nearest wastewater treatment plant.

Cutting wheel pumps are the first choice for pumping small amounts of wastewater containing fecal matter. The cutting wheels shred all the larger components of the wastewater during operation, allowing the use of smaller pipe cross-sections. The pipeline network thus remains optimally protected against deposits and blockages.

The wastewater only remains in the closed pipeline network for a short time, so that rotting processes and odor emissions cannot occur. Pressure drainage is ideal, especially for longer distances and difficult topographical conditions. Following the course of the terrain, differences in altitude can be overcome without any problems.

The investment and operating costs of pressure drainage are often significantly more economical compared to gravity sewer systems.

VARIANT pump stations are equipped with the non-return ball valves and reliably protect your property against backwater from the public network.

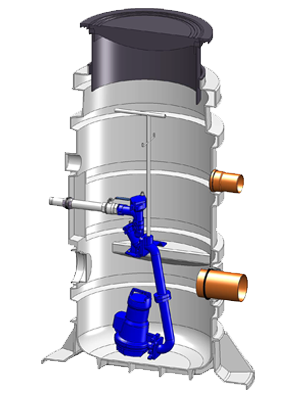

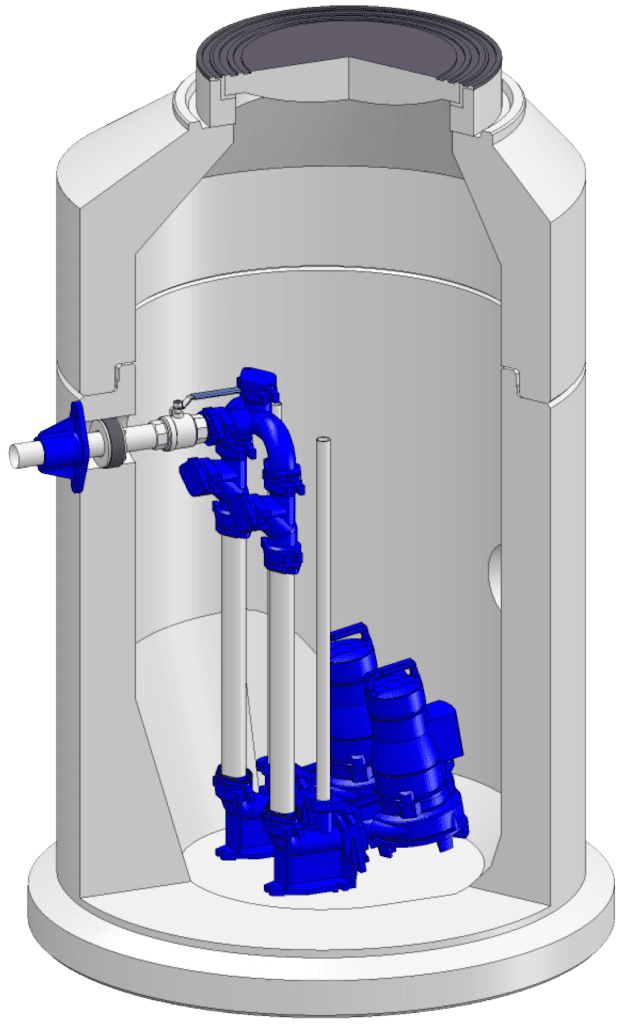

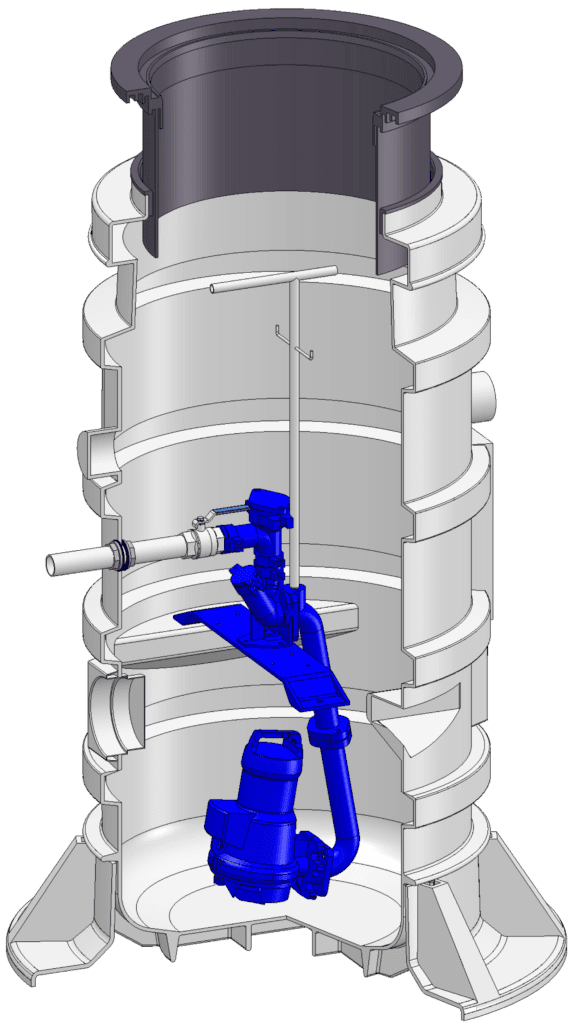

Druckentwässerung VARIANT mit Betonbehälter

Pressure drainage VARIANT with concrete tank

Features

Pump station for greater inlet depths

- Robust reinforced concrete shaft

- Covers up to Class D (Truck Accessible)

- Pumps with foot installation

- Single or Double Unit

- Armatures in DN 40 or DN 50

- Armatures in cast iron or stainless steel

- Inklusive buoyancy control

- Fully Electronic Control Unit

- Control System for Outdoor Column or Building Installation

- Optional Flushing Connection

- Optional Vacuum Breaker

Shaft Systems

Pump station in concrete construction

- Zulauftiefe: 0,90 – 9,00 m

- Einbautiefe: 1,68 – 10,00 m

- Shaft Diameter: Inside 1.000 mm / Outside 1.300 mm

- Storage Volume up to Inlet: Variable, Starting from 300 liters

- Pipe Connections: Individually Customizable

- Cone or Flat Cover

- Covers: BEGU / Cast Iron in Class B/D and Stainless Steel in Class A

- Ventilation

- Ladder

Armatures

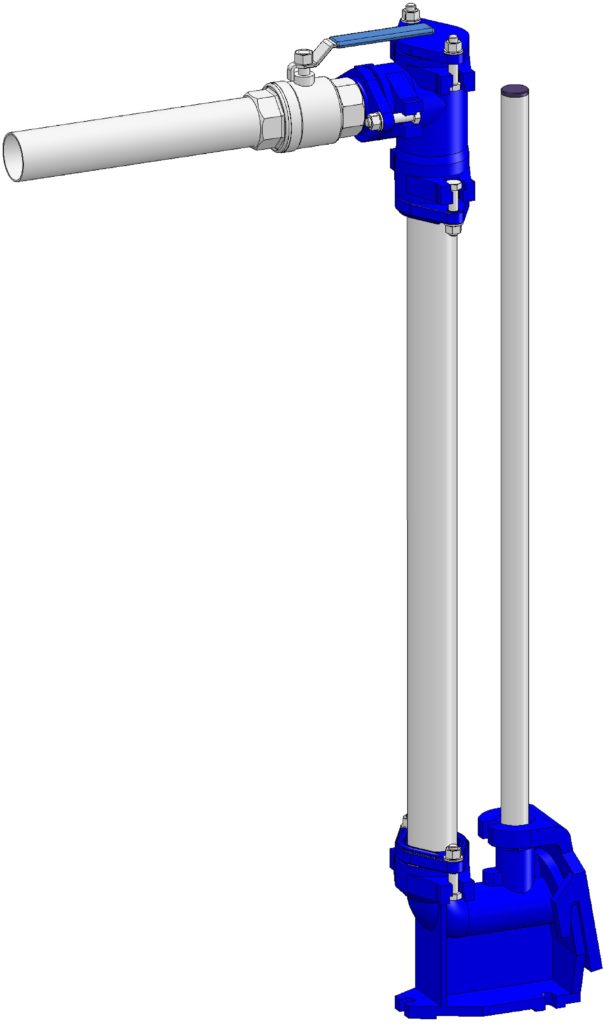

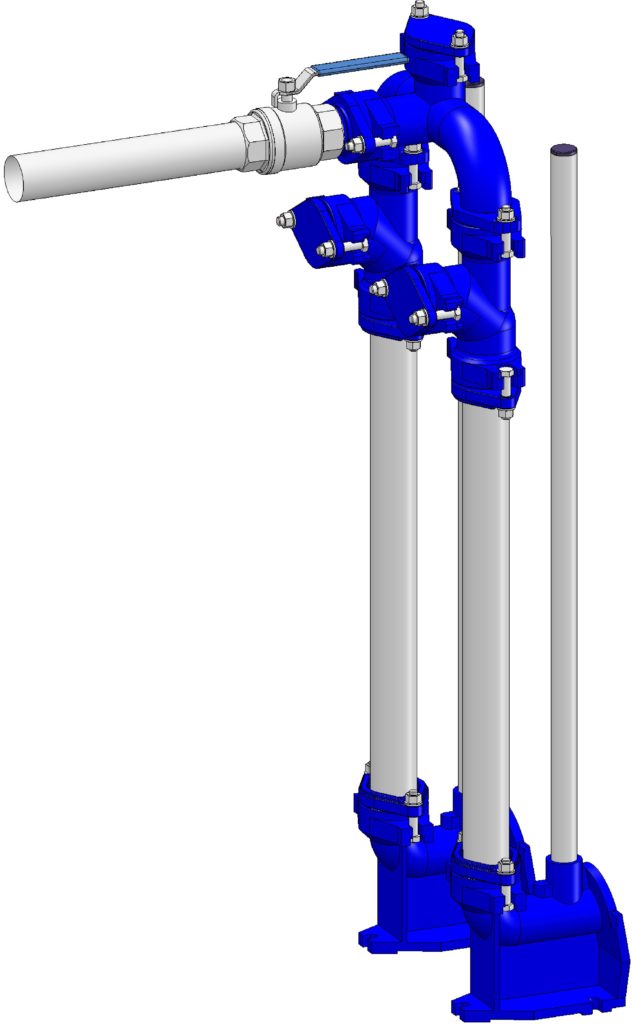

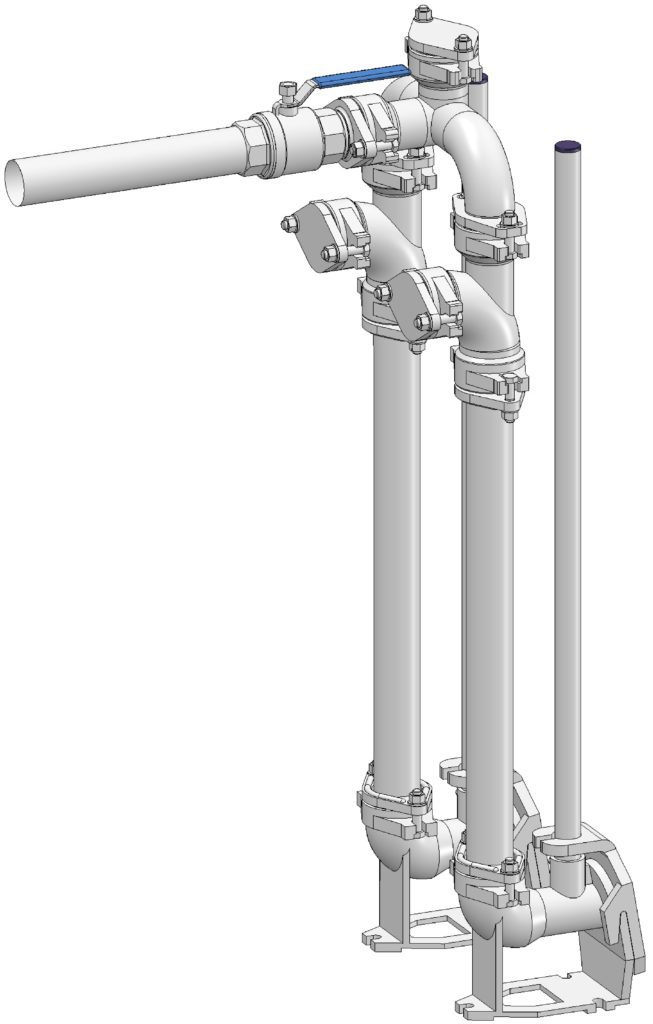

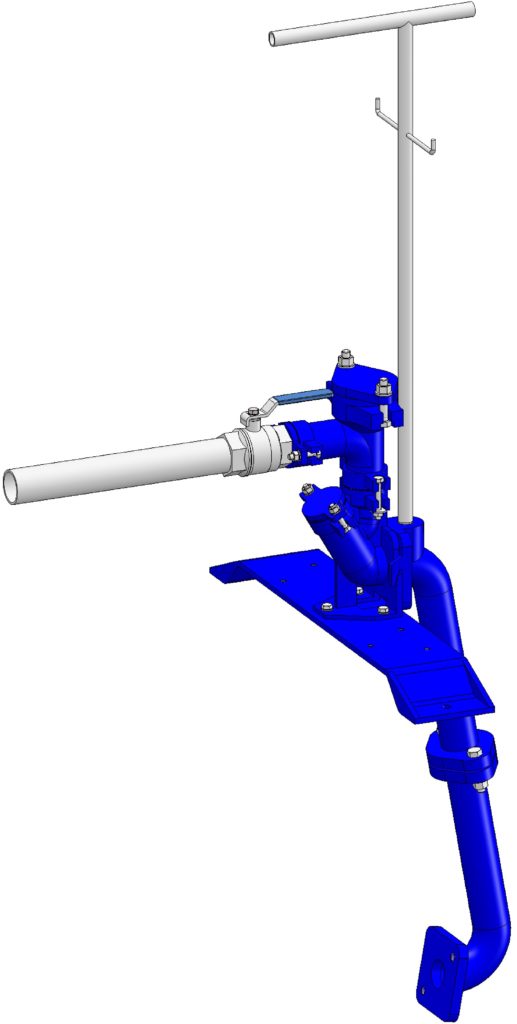

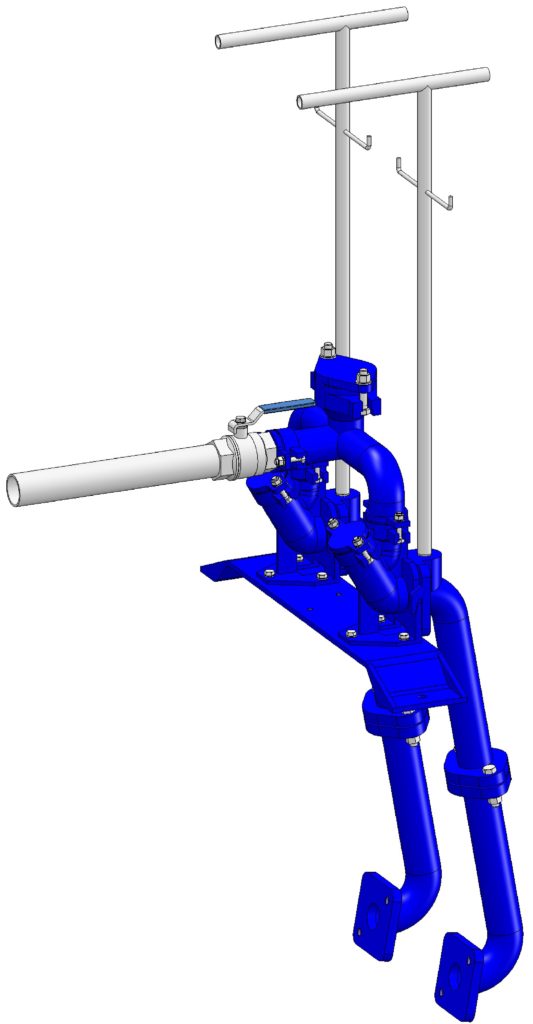

Cast Iron Armatures in DN 50 with Foot Installation

Cast Iron Armatures in DN 50 with Foot Installation

Single Unit

Double Unit

- Ductile Iron Armatures with Powder Coating

- Piping Made of Stainless Steel

- Piping: Stainless Steel, Extendable as Needed Depending on Shaft Depth

- Easy Pump Installation: Pumps Can be Easily Inserted into the Coupling from above without Entering the Shaft

- Pump Removal: Possible at any Time without Shutting off the Gate Valve

- Ball Check Valve: Prevents Backflow into the Pumping Station

- Shut-Off Gate Valve: Allows the Piping to be Closed for Maintenance Purposes

- Optional Features: Flushing Connection, Vacuum Breaker

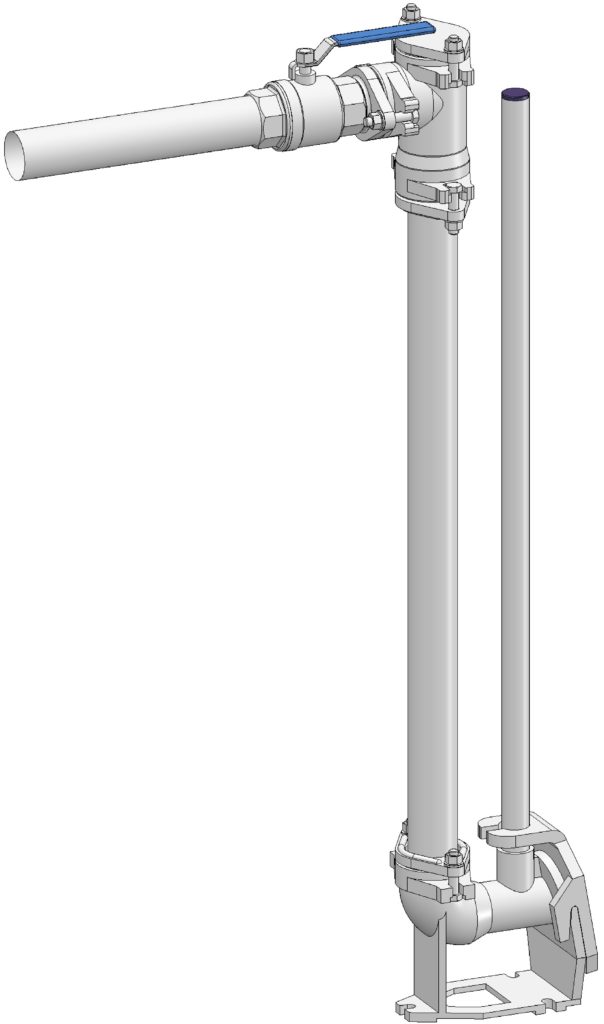

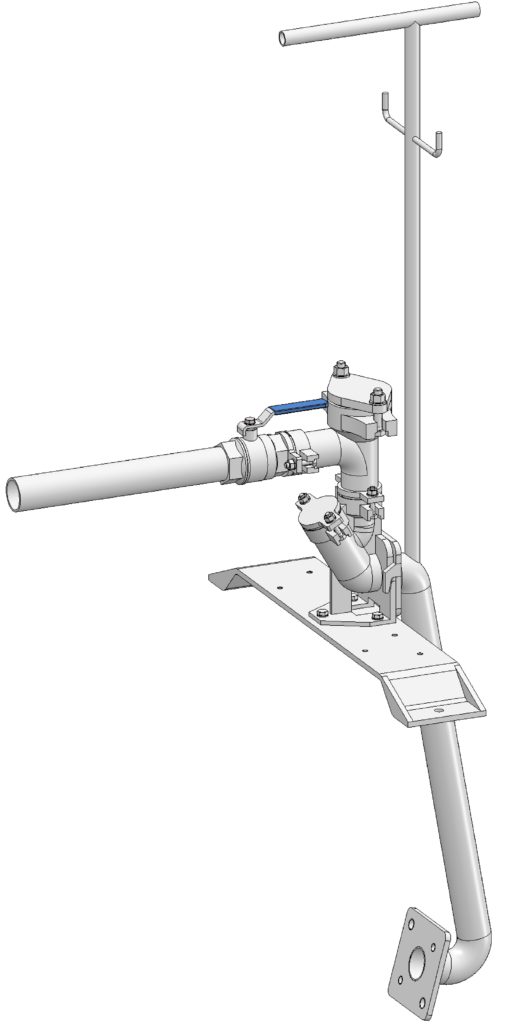

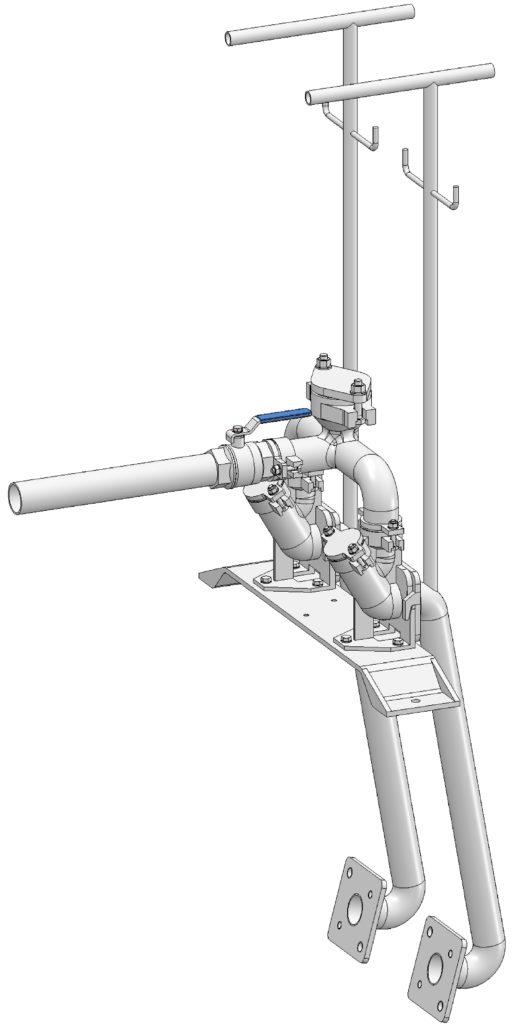

Stainless Steel Armatures in DN 40/50 with Foot Installation

Single Unit

Double Unit

- Corrosion-Resistant Armatures and Piping Made of 100% Stainless Steel

- Piping: Stainless Steel, Extendable as Needed Depending on Shaft Depth

- Easy Pump Installation: Pumps Can be Easily Inserted into the Coupling from above without Entering the Shaft

- Pump Removal: Possible at any Time without Shutting off the Gate Valve

- Ball Check Valve: Prevents Backflow into the Pumping Station

- Shut-Off Gate Valve: Allows the Piping to be Closed for Maintenance Purposes

- Optional Features: Flushing Connection, Vacuum Breaker

Pumps

For optimal performance and flow velocity, armatures, pressure lines, and pumps must be precisely tailored to the requirements of your construction project. Our range includes pumps with cutting wheel systems for small volumes of wastewater containing impurities, as well as pumps with free-flow impeller systems. Both variants are available with or without explosion protection. For specific types of wastewater, pumps with special resistance to aggressive substances may be required.

Don't leave the selection of your pump to chance—let us assist you in choosing the right configuration. To provide you with the best pump for your project, we collaborate with leading wastewater pump manufacturers. Our armature system is compatible with nearly all standard pumps featuring a DIN flange.

Control Unit

Our Control Units Reliably Operate and Monitor Your VARIANT Pump Station. The control system can be installed indoors using wall mounting or outdoors in a weatherproof column. Depending on your application, we offer a well-coordinated solution that integrates control units, level measurement, armatures, pumps, and the shaft.

Control Unit CEB / CDB

- Connection Capacity: Up to 5,5 kW / 9 A

- Dimensions: W/H/D = 265 x 270 x 145 mm

- Level Measurement: Differential Pressure, Float Switch, Pressure Sensor

- Touch Color Display: Backlit

- Error Log: Full-text Display

- Hand – 0 – Automatik Einstellung

- 3 Potential-Free Contacts

- Optional: GSM Modem with Qualified Notifications

- Operating Hours Recording, Current Measurement, and Thermal Monitoring of Pumps

- Alerts: Overcurrent, Overheating, High Water Level, Runtime Monitoring

- Optional Air Entrainment for Differential Pressure Measurement

- Optional Power Failure Monitoring with Battery Backup

- Visual and Audible Alarm Notifications

- Motor Protection Switch

- Main Switch

- External Pump Locking Available

Control unit BEN / BDN

- Connection Capacity: Up to 5,5 kW / 9 A

- Dimensions: W/H/D = 200 x 220 x 110 mm

- Level Measurement: Differential Pressure, Float Switch

- Text display: with Illuminated Digits

- LED Error Indicator: on Front Cover

- Manual Operation: with Push Button

- 1 potential-Free Contact

- Optional: GSM Modem with collective fault notification

- Operating Hours Recording, Current Measurement, and Thermal Monitoring of Pumps

- Alerts: Overcurrent, Overheating, High Water Level, Runtime Monitoring

- Optional Air Entrainment for Differential Pressure Measurement

- Optional Power Failure Monitoring with Battery Backup

- Visual and Audible Alarm Notifications

- Electronic Motor Protection

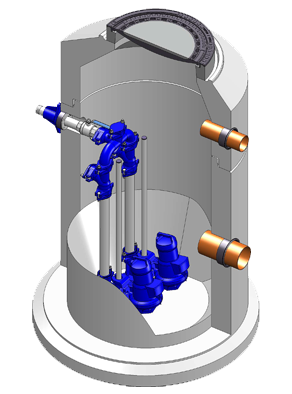

Druckentwässerung VARIANT mit PE-Behälter

Pressure Drainage VARIANT with PE Tank

Features

VARIANT Pump Station for Single/ Two-Family Hauses

- Robust Polyethylene LDPE Shaft

- Covers up to Class D (Truck Accessible)

- Pumps with Traverse Suspension

- Single or Double Unit

- Armatures in DN 40

- Armatures in Cast Iron or Stainless Steel

- Optional Anti-Buoyancy System

- Fully Electronic Control Unit

- Control System for Outdoor Column or Building Installation

- Optional Flushing Connection

- Optional Vacuum Breaker

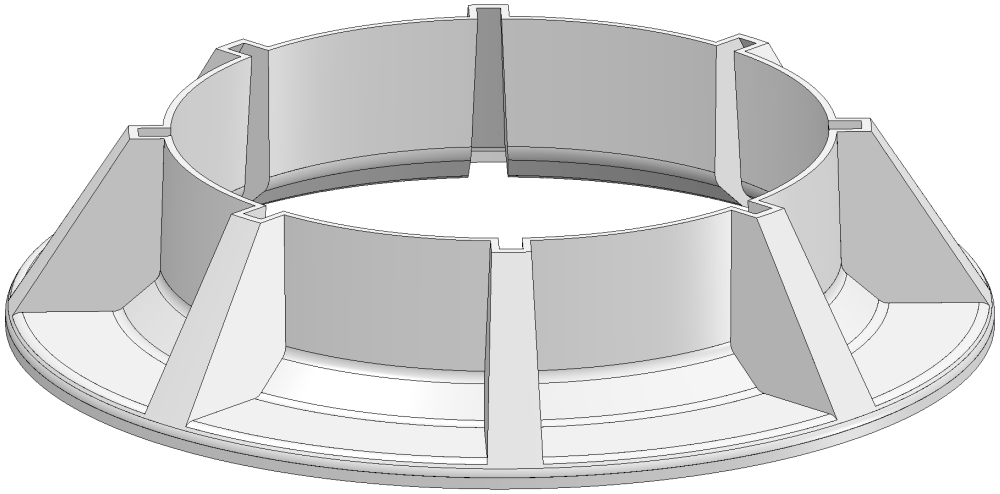

Shaft Systems

LDPE Pumping Station

- Zulauftiefe: 1,26 – 1,96 m

- Einbautiefe: 1,78 – 2,48 m

- Shaft Diameter: 800 mm

- Storage Volume up to Inlet: Approx. 300 liters

- Inlet Connection: 2 x KG DN 150

- Technical and Ventilation Connection: 2 x KG DN 100

- Telescopic Dome for Precise Height Adjustment

- Plastic covers up to 200/600 kg or as BEGU class B/D in Ø 600 mm

- Ventilation

- Anti-Buoyancy System

Required from a Groundwater Level of 50%

Armatures

Cast Iron Armatures in DN 40 with Traverse Suspension

Single Unit

Double Unit

- Ductile Iron Armatures with Powder Coating

- Piping: Stainless steel

- Coupling Foot: Located on the cross traverse

- Easy Pump Installation: Pumps Can be Easily Inserted into the Coupling from above without Entering the Shaft

- Pump Removal: Possible at any Time without Shutting off the Gate Valve

- Ball Check Valve: Prevents Backflow into the Pumping Station

- Shut-Off Gate Valve: Allows the Piping to be Closed for Maintenance Purposes

- Optional Features: Flushing Connection, Vacuum Breaker

Stainless Steel Armatures in DN 40 with Traverse Suspension

Single Unit

Double Unit

- Corrosion-Resistant Armatures and Piping Made of 100% Stainless Steel

- Coupling Foot: Located on the cross traverse

- Easy Pump Installation: Pumps Can be Easily Inserted into the Coupling from above without Entering the Shaft

- Pump Removal: Possible at any Time without Shutting off the Gate Valve

- Ball Check Valve: Prevents Backflow into the Pumping Station

- Shut-Off Gate Valve: Allows the Piping to be Closed for Maintenance Purposes

- Optional Features: Flushing Connection, Vacuum Breaker

Pumps

For optimal performance and flow velocity, armatures, pressure lines, and pumps must be precisely tailored to the requirements of your construction project. Our range includes pumps with cutting wheel systems for small volumes of wastewater containing impurities, as well as pumps with free-flow impeller systems. Both variants are available with or without explosion protection. For specific types of wastewater, pumps with special resistance to aggressive substances may be required.

Don't leave the selection of your pump to chance—let us assist you in choosing the right configuration. To provide you with the best pump for your project, we collaborate with leading wastewater pump manufacturers. Our armature system is compatible with nearly all standard pumps featuring a DIN flange.

Control Unit

Our Control Units Reliably Operate and Monitor Your VARIANT Pump Station. The control system can be installed indoors using wall mounting or outdoors in a weatherproof column. Depending on your application, we offer a well-coordinated solution that integrates control units, level measurement, armatures, pumps, and the shaft.

Control Unit CEB / CDB

- Connection Capacity: Up to 5,5 kW / 9 A

- Dimensions: W/H/D = 265 x 270 x 145 mm

- Level Measurement: Differential Pressure, Float Switch, Pressure Sensor

- Touch Color Display: Backlit

- Error Log: Full-text Display

- Hand – 0 – Automatik Einstellung

- 3 Potential-Free Contacts

- Optional: GSM Modem with Qualified Notifications

- Operating Hours Recording, Current Measurement, and Thermal Monitoring of Pumps

- Alerts: Overcurrent, Overheating, High Water Level, Runtime Monitoring

- Optional Air Entrainment for Differential Pressure Measurement

- Optional Power Failure Monitoring with Battery Backup

- Visual and Audible Alarm Notifications

- Motor Protection Switch

- Main Switch

- External Pump Locking Available

Control unit BEN / BDN

- Connection Capacity: Up to 5,5 kW / 9 A

- Dimensions: W/H/D = 200 x 220 x 110 mm

- Level Measurement: Differential Pressure, Float Switch

- Text display: with Illuminated Digits

- LED Error Indicator: on Front Cover

- Manual Operation: with Push Button

- 1 potential-Free Contact

- Optional: GSM Modem with collective fault notification

- Operating Hours Recording, Current Measurement, and Thermal Monitoring of Pumps

- Alerts: Overcurrent, Overheating, High Water Level, Runtime Monitoring

- Optional Air Entrainment for Differential Pressure Measurement

- Optional Power Failure Monitoring with Battery Backup

- Visual and Audible Alarm Notifications

- Electronic Motor Protection