The plastic PE-HD is corrosion-resistant against gases and reliably resistant to chemical components in wastewater. The smooth inner surface prevents deposits.

The pumping station is delivered to the construction site fully equipped in one piece and lifted directly from the truck into the excavation pit.

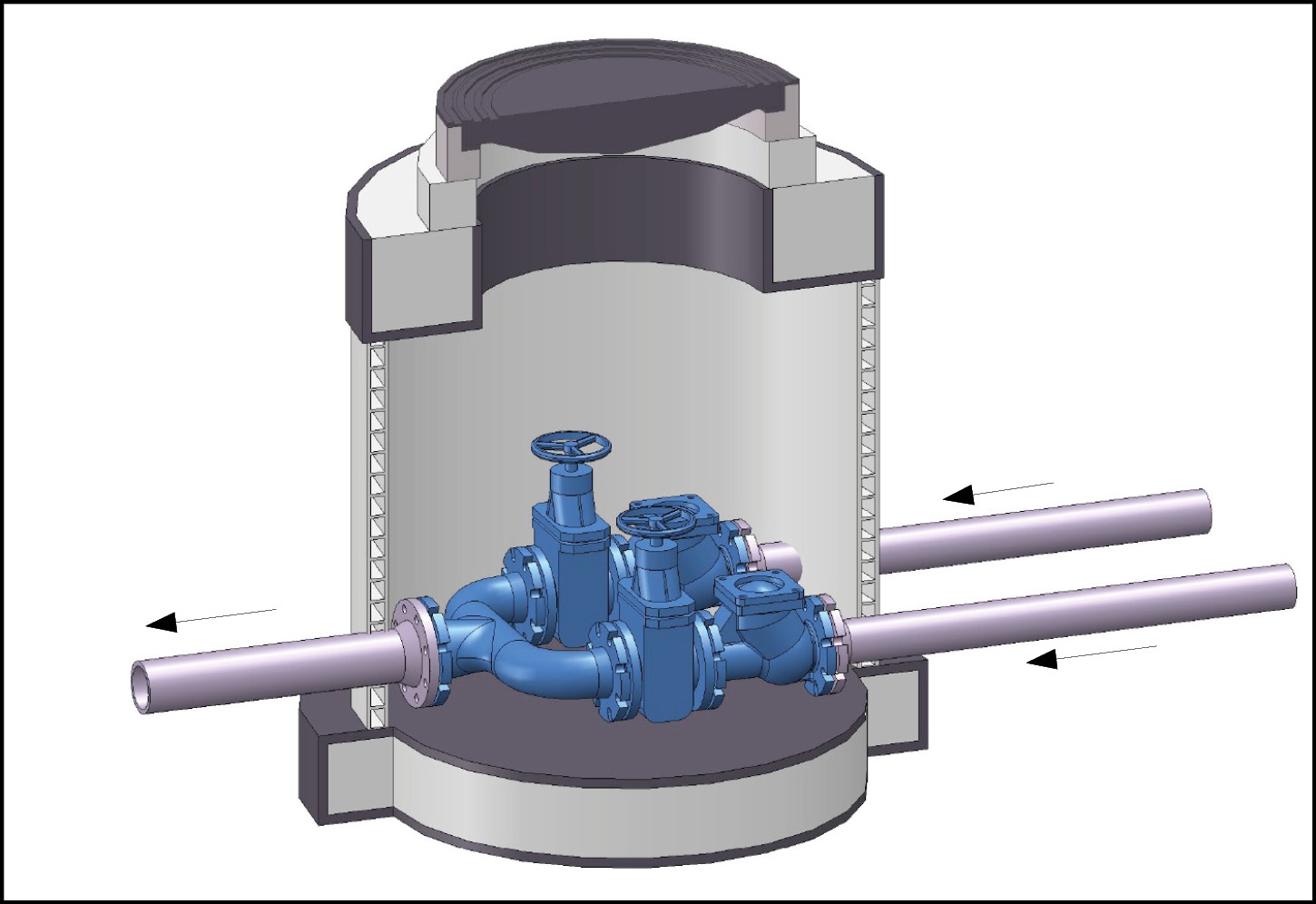

Depending on the requirements, a buoyancy protection system is already factory-welded to the structure. This takes the form of an enlarged PE-HD cantilever plate with a steelreinforced concrete core.

Kordes armatures stand out for their highly break-resistant materials and a lowmaintenance design with minimal assembly and fastening components.

The lightweight DORANT variants are especially easy to transport, making them suitable for use in hard-to-reach terrain.

The DORANT pumping station is also suitable for water protection areas, as the tank is constructed with double walls and can be equipped with continuous leak monitoring upon request.

Submersible Wastewater Pumping Stations are ideally suited for municipal and industrial wastewater, as well as surface water.

Special stress factors affecting pumping stations in municipal areas include heavy rainfall, biogas emissions, fats, and fibrous materials. In the case of industrial wastewater, the challenge lies in aggressive chemical loads due to the substances involved. Applications for surface runoff from parking lots and roads not only have to manage heavy rain events but also address the issue of increased salt content.

Each pumping station must be specifically designed and configured to ensure adequate durability for long-term use. For the shaft structure, static safety against buoyancy is often required due to the presence of groundwater at certain locations. Our pre-assembled pumping stations reduce construction time, significantly cutting costs related to groundwater management, wastewater disposal, and traffic disruptions during the construction phase.

A frequently requested service from our company is planning support. The focus here is on the planning of wastewater pump stations, including the calculation of pumps, calculation of pressure pipelines up to the planning of pressure pipe flushing stations. The planning of EMSR and control technology are also among our strengths.

When you place your order, you will receive a detailed 2D and 3D drawing from us for your building project. This serves to visualize your new pumping station and facilitates technical optimization before the start of construction. Only when everything is perfect, we start production.

High-Density Polyethylene (PE-HD) is a versatile plastic material that is among the most widely used in industrial and municipal wastewater applications.

Thanks to its organic composition of purely carbon and hydrogen, which prevents the diffusion of toxic substances, PE stands for sustainability and an excellent environmental profile.

100% Ductile Cast Iron,

Powder Coated

DN 80 – 200

Ductile Cast Iron

Powder Coated

and Stainless Steel

DN 80 – 200

100% Stainless Steel

DN 80 – 100

Delivery as a Kit: Delivered as a kit that must be fully assembled on-site.

Complete Delivery: The pumping station is delivered as a single unit, including all technical components.

Risk of Installation Errors

No Installation Errors: Installation errors are eliminated.

Installation Time: 2 Days and More

Quick Installation Time: Installed within 2 Hours.

Concrete Cover: Placed on the Shaft Casing Pipe Using a Sealing Ring

Cover Plate: Made of PE-HD with a Steelreinforced Concrete Core, Permanently Welded to the Shaft Casing Pipe.

Corrosion-Prone Exposed Concrete: Exposed concrete is susceptible to corrosion unless covered at the construction site.

Fully Lined: Underside and Dome Entry Fully Lined with PE-HD.

Potential for Leakage: Installation and Agerelated Leakage can Be Expected.

Sealed Construction: The Cover Plate is Securely and Tightly Welded to the Shaft Casing Pipe.

Load Transfer Ring: Concrete Load Transfer Ring must Be Poured On-site According to Requirements.

Direct Load Transfer: The Load is Transferred Directly from the Cover Plate to the Shaf Casing Pipe.

Base Plate in PE-HD

PE-HD Base Plate with Steel-Reinforced Concrete Core

Base Plate in PE-HD: Groundwater-Related Bulging can Cause Stress and Vibrations in the Armatures.

No Stress or Vibrations: The Special Kordes Connection System between the Concrete and PE-HD Eliminates Stress and Vibrations.

Foundation Slab: A Concrete Foundation Slab must Be Poured On-Site, onto whic the PE-HD Shaft Is Placed.

– Buoyancy Protection: If Buoyancy Protection is Required, It must be Done Separately Using Concrete Backfill.

Factory-Welded Buoyancy Protection: The Buoyancy Protection is Factory-Welded as a Cantilevered Base Plate to Meet Specific Requirements.

For optimal flow performance and velocity, armatures, pressure lines, and pumps must be precisely tailored to the requirements of your construction project. Our range includes pumps with cutting wheel systems for small wastewater volumes with particulates, as well as pumps with free-flow impeller systems. Both types are available with or without explosion protection. For certain wastewater types, pumps with special resistance to aggressive substances are necessary.

Don’t leave the selection of the right pump to chance; let us assist you in making the correct choice. To ensure we offer the pump best suited for your project, we collaborate with leading manufacturers of wastewater pumps. Our armature system is compatible with almost all standard pumps with a DIN flange.

With our Kordes control systems, we can operate single, double, or multiple units. Our controls are used by commercial and municipal facility operators and can be customized with electronic components as needed. For municipal wastewater management, we also provide PLC-controlled systems, complete with process visualization and remote monitoring technology. We are happy to supply a matching control cabinet for your project. At our facility, the control system and desired components are fully assembled and tested in the control cabinet according to your specifications.

Pumping stations require a safe entry option. For this purpose, we install stainless steel ladders with safety steps available in widths of 300mm and 400mm. A retractable entry aid provides additional safety when entering. For deeper pumping stations, we offer a climbing protection system or an intermediate platform in accordance with accident prevention regulations (UVV) for fall protection.

For a secure and sealed connection between the shaft and piping, we offer Kordes ConFix sealing insert systems. These systems provide a permanently elastic and tight seal between the pipe and the concrete or PE-HD wall. Pipes made of cast iron, steel, and plastic are gas- and watertight, sealed within core drill holes or protective sleeves. The robust connection is achieved using an NBR rubber ring compressed between two V2A stainless steel flanges.

In the case of pumping stations, it is sometimes desirable to be able to shut off the supply lines for work in the shaft. For this we offer plug-in or spindle gate valves for the appropriate pipe diameter. It is operated mechanically or by an electric drive. The controller can be connected to the BMS.

For proper shaft ventilation, appropriate stainless steel or PE-HD pipes should be installed within the shaft. To terminate the underground piping, we offer stainless steel ventilation chimneys in DN 100 / DN 150. The stainless steel cover can be optionally equipped with a vent cap.

We offer shaft covers tailored to your requirements, available in square or round shapes, made from BEGU, cast iron, or stainless steel. The shaft system meets load class SLW 60, allowing cover selection from class A to D.

Armatures are typically located within the pumping station, but some operators prefer having them in a separate shaft, which we offer as a prefabricated unit in PE-HD or reinforced concrete. Inductive flow measurement devices or ventilation valves can also be conveniently installed in separate shafts.

We optionally offer a suitable technical building for your pumping station. We coordinate the equipment with you individually to ensure an optimal solution for future operations.