The BIOclear vario-S wastewater treatment plant is the ideal treatment system when sludge treatment is required in addition to wastewater treatment. This plant is mostly used in larger units for towns and residential areas with separate or combined sewage systems, in commercial, industrial companies and holiday resorts, as well as all comparable applications for the treatment of domestic wastewater. For the sewage treatment plant we supply the technical equipment for already existing tanks or newly constructed in-situ concrete tanks.

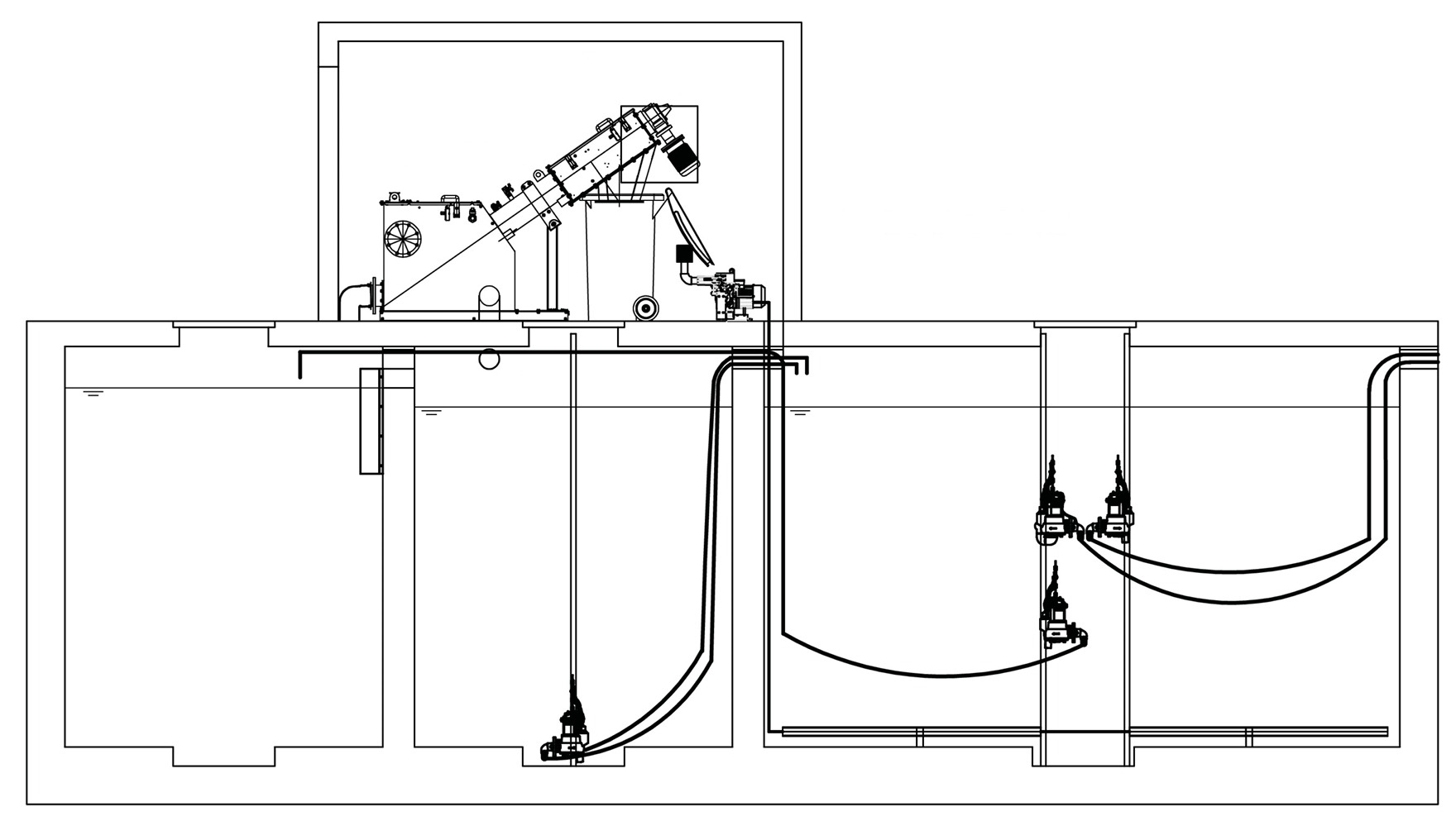

Side View

Sludge Storage

Buffer

SBR

Top View

Sludge Storage

Buffer

SBR

The SBR (Sequencing Batch Reactor) process is a proven technology for the treatment of domestic wastewater. The treatment plant consists of the buffer tank, SBR reactor and sludge storage tank for storing the excess sludge. Pre-treatment in the BIOclear vario-S consists of a spiral screen. The wastewater is then stored in the buffer tank and further treated according to the set cycle program as follows:

Feeding the SBR Reactor from the Buffer Tank.

Aeration and Mixing of the Activated Sludge in the SBR Reactor for the Biological Process.

Sedimentation Phase to Separate the Clear Water from the Activated Sludge.

Pumping out the Treated Wastewater

As the first treatment stage, the wastewater first flows through the pre-sedimentation. Here, the raw sludge is settled together with the excess sludge as bottom and scum. As soon as the maximum sludge level is reached, discharge must take place.

For optimum adjustment of the biology, all pumps can be easily moved by means of a sliding pipe guide and always set to the correct height to suit the connection size. Underload operation can thus be effectively prevented.

The control of the wastewater treatment plant is carried out by a specially programmed PLC with display and operating options of a clearly arranged touch display. The measuring and dosing technology is individually selected according to the requirements in order to achieve the required treatment performance with the greatest possible reliability. For smooth operation management, we offer our own solution of remote data transmission and parameterization.

All fixing components and pipelines installed in the treatment tank are corrosion-resistant and made of stainless steel or plastic. The replacement of pumps and diffuser systems can be done during operation, so that they can be removed without having to get in. When using disc diffusers, the air distribution can be controlled by means of sliders from the access opening, so that an optimal oxygen supply of the activated sludge is possible.

In accordance with this concept, our supplied plants run with high flexibility together with great operational reliability.

Filling

Sludge Storage

Buffer

SBR

Sieve

Inflow / Outflow

Sludge Drying

Return to Buffer

Sludge treatment and dewatering is performed as in the following steps:

Aeration System with Membrane Tube and Grid in the SBR Reactor

Side Channel Compressor in the Technical Shaft

View of the Control Cabinet

Structure of the Control Unit

Data Connection of the Control Unit

EX-protection of the Wastewater Treatment Plant with Complete Documentation and Testing

Pressure Sensors for Level Measurement in Buffer and SBR, as well as for the Exact Calculation of the Flow Rate.

Measurement Technology with Probes for:

Dosing Technology for: